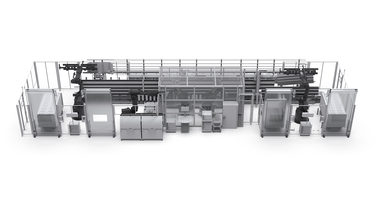

System reference

Carcase drilling machine for kitchen industry

System solutions | Mechanical and plant engineering | Wood and composites

Challenge

Machining of carcase parts with different machining contents and additional fitting sets. Batch size 1 production. Interlinking with AGV-controlled workpiece supply to the system.

Solution

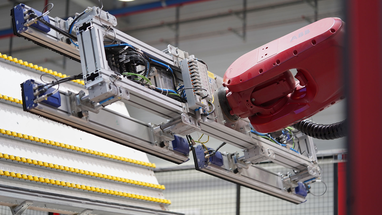

Accuracy is achieved via a robot compensation system developed in-house. The system's performance is achieved by stations working in parallel. The system is loaded and unloaded during non-productive time. You can find more information here: Carcase processing/batch size 1 - Zimmer Group (zimmer-group.com)

Highly flexible production line for processing carcase parts in batch size 1

- Highly flexible shuttle circulation as workpiece transport and clamping system

- Automatic loading and unloading with direct connection of customer AGVs

- Precision-compensated industrial robots for the machining processes

- Drilling head equipped with vertical and horizontal drilling spindles, Clamex, milling and grooving unit

- Placement of metal and plastic fittings from pre-assembled trays

- Integrated component return for rear side processing

- Direct integration into the customer's production control system

- Minimal space requirement

- High availability and easy maintenance thanks to the use of industrial robots

Technical data:

- Processing of coated chipboard and MDF panels with dimensions from 240 mm x 120 mm up to 2800 mm x 1300 mm

- Production output of up to 3 parts/min