Pellet printing for prototyping, component optimization and small-batch production

Discover the future of manufacturing technology with our advanced 3D printing service. We offer you the opportunity to manufacture components in the shortest possible time and without the need for expensive tooling. Our expertise in the field of 3D printing opens up a wide range of applications for prototype construction, optimization of assemblies and small-batch production in various branches of industry.

YOUR BENEFITS

- Geometric flexibility in component manufacturing

- Glass fiber-reinforced plastics can also be printed

- Supporting structures can be printed in a different material

- Two materials can be printed at the same time

From the 3D model to series production

Our 3D printing service expands on our in-house process technologies and unlocks new potential. In addition to additive manufacturing, we also rely on proven processes such as plastic injection molding and MIM technology for series production. We offer our customers a comprehensive service package from prototype development and testing to series production and component optimization – all from a single source.

Design engineering

Prototype

Series

Spare parts

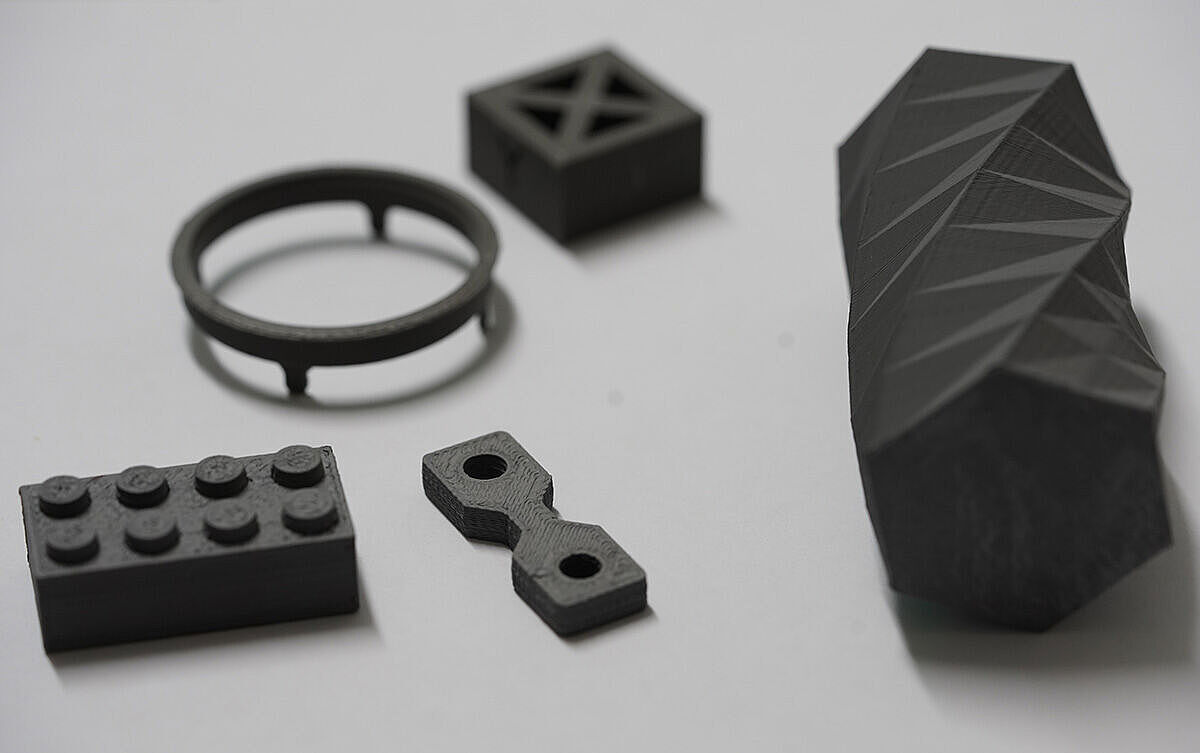

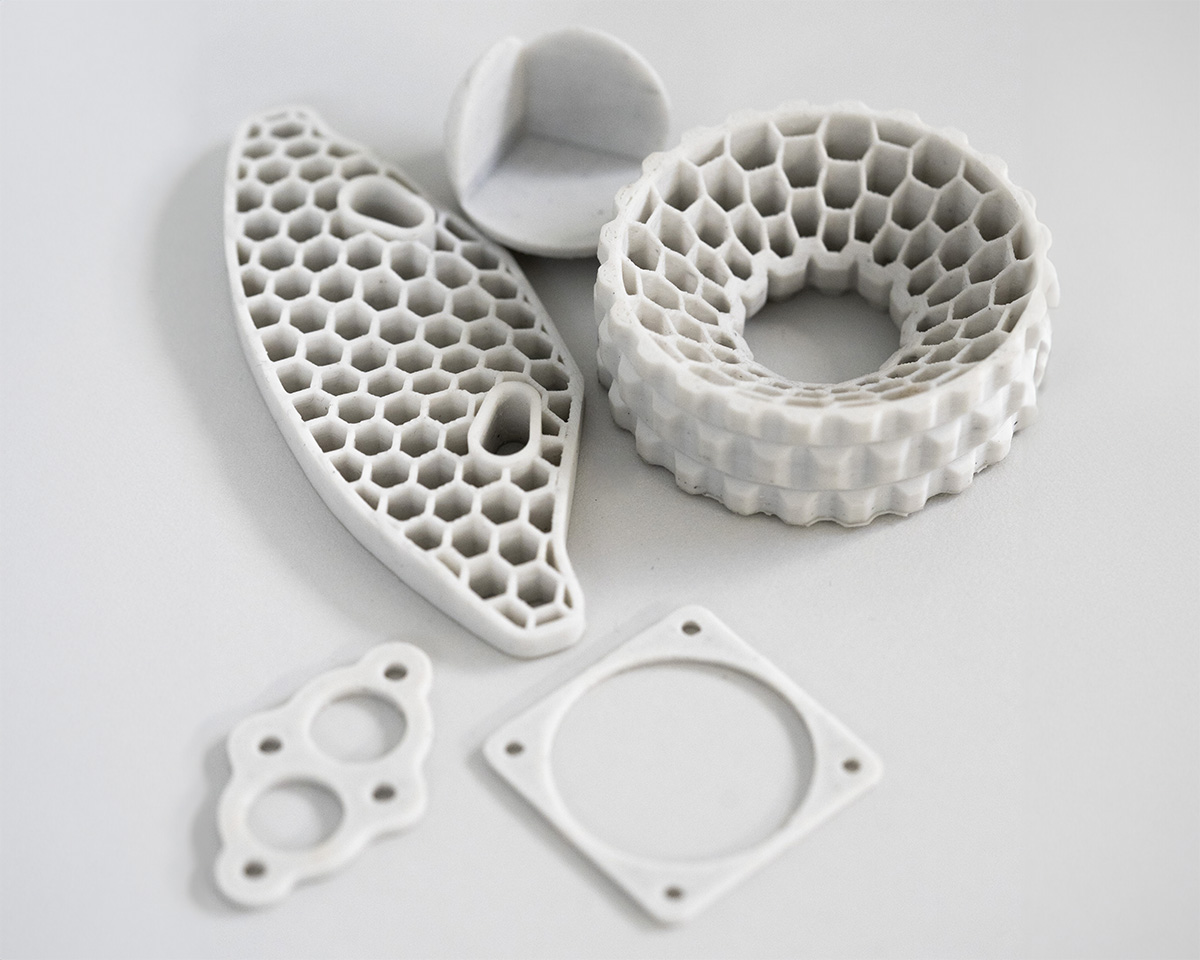

GEOMETRIC FLEXIBILITY AND MATERIAL VARIETY

- Geometric flexibility: Achieve complex geometries and intricacies in component manufacturing.

- Material variety: Alongside standard plastics, we can also process fiberglass-reinforced plastics.

- Multi-material processing: Our 2-extruder technology allows us to print supporting structures made of a different material and to work with two different materials at the same time, which also enables 2-component processing.

KNOW-HOW IN ONE PLACE

Different process technologies

In addition to 3D printing, we also offer plastic injection molding, metal injection molding (MIM) and elastomer technology for the series production of parts.

Customized consultation

We support you from development to series production and offer you customized consultation on the process technology that is best suited for your workpiece.

Many years of experience

Thanks to our in-house expertise in a wide range of technologies, we can respond quickly and efficiently to specific requirements.

Our core business in 3D printing

Prototyping

Prototyping using 3D printing is a typical application for this technology. It makes it possible to quickly and cost-effectively implement ideas and visions in prototypes without the need for expensive tool construction. This allows you to transform your ideas and visions into a unique end product in just a few days.

Small-batch production

3D printing offers a previously unheard-of opportunity to produce small batches economically. Unlike conventional manufacturing, 3D printing has the advantage of not requiring any production tools. It also eliminates the need for warehousing and expensive lead times.

ASSEMBLY OPTIMIZATION

Improved production processes and assemblies through the use of 3D printing technology. This method makes it possible to develop, engineer and manufacture individual components more efficiently.

A VARIETY OF MATERIALS

Our 3D printing service enables the processing of a wide range of materials, including:

Metals

All common MIM materials for robust and precise components.

Plastics

Use of all conventional injection molding materials.

Thermoplastic elastomers

Thermoplastic elastomers for flexible applications.

Ceramics

High-quality ceramic materials for special requirements.

Frequently asked questions

In 3D printing, a three-dimensional object is built up layer by layer. A 3D model designed using CAD software is used as a template. The most common file types are STL (Standard Triangulation Language), VRML (Virtual Reality Modeling Language) and X3D (Extensible 3D). The model is then built up in layers of fusible materials. Various plastics, metals and even porcelain can be used as materials.

No elaborate tool production is needed for 3D printing. This means it is possible to develop prototypes faster than with plastic injection molding. It is also possible to optimize assemblies and efficiently manufacture small batches. Complex shapes and quick design adjustments can be made easily, speeding up the processes for prototype manufacturing or small-batch production. This results in cost savings compared to conventional manufacturing processes, especially for small quantities.

We offer the processing of metals, plastics, thermoplastic elastomers and ceramics. We are happy to advise you on choosing the right materials for your workpiece. Get in touch with us!

Yes, 3D printing offers a high degree of geometric flexibility, which means that even complex components can be manufactured.

Yes, we offer the option of working with two extruders to print supporting structures and main structures made of different materials, including 2-component processing.

3D printing is ideal for small-batch production, for developing workpieces including prototyping or when frequent changes need to be made to the component. The big advantage here is the significantly shorter throughput times.

When it comes to large-scale production, where components no longer need to be modified, injection molding may be the right choice.

However, there are other factors (tolerances, component size, lead times, design complexity, etc.) that need to be considered in order to choose the right manufacturing process. In a customized consultation, we will show you the advantages and disadvantages of the respective processes and the options for manufacturing your workpieces. Get in touch with us today!