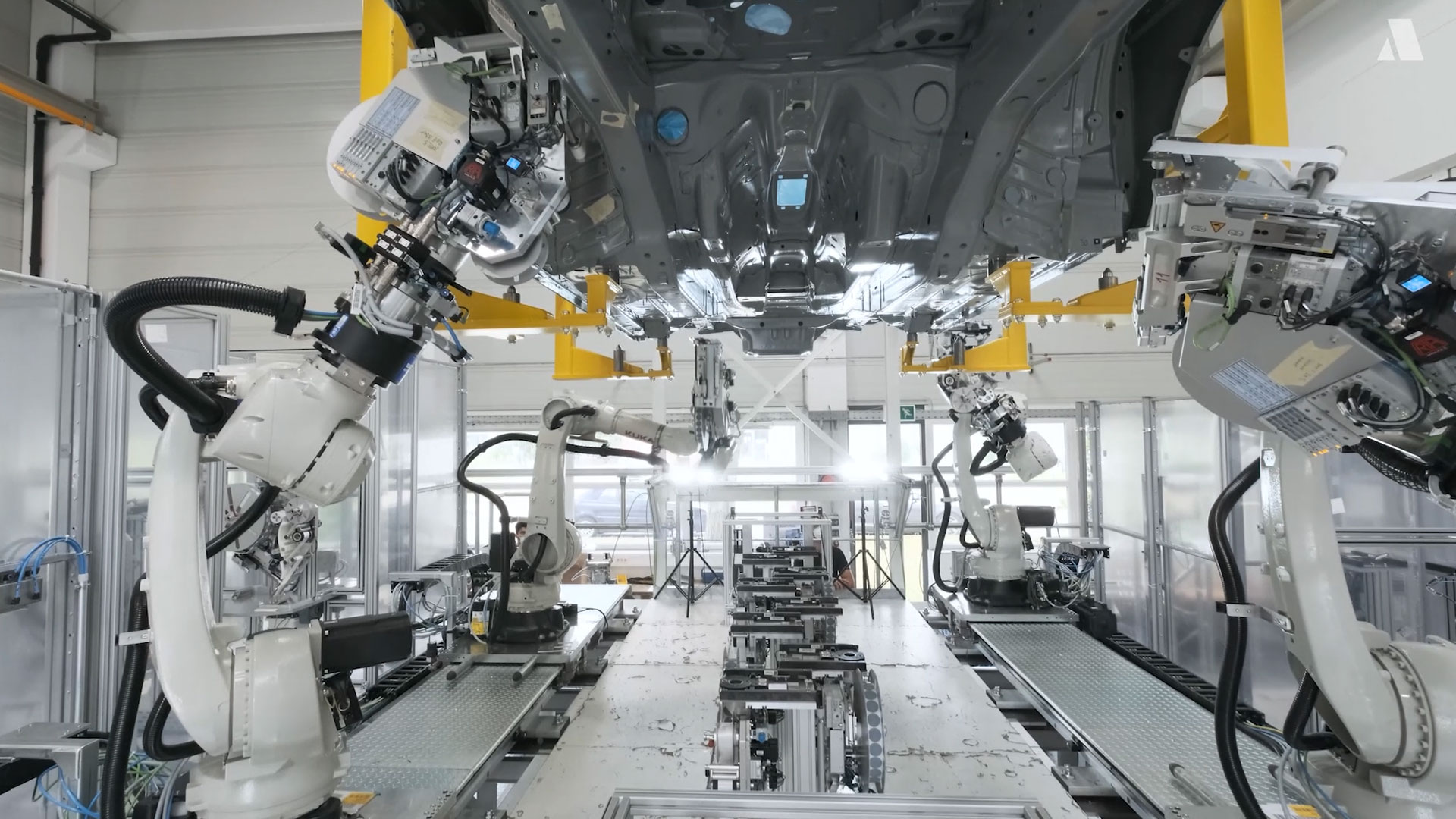

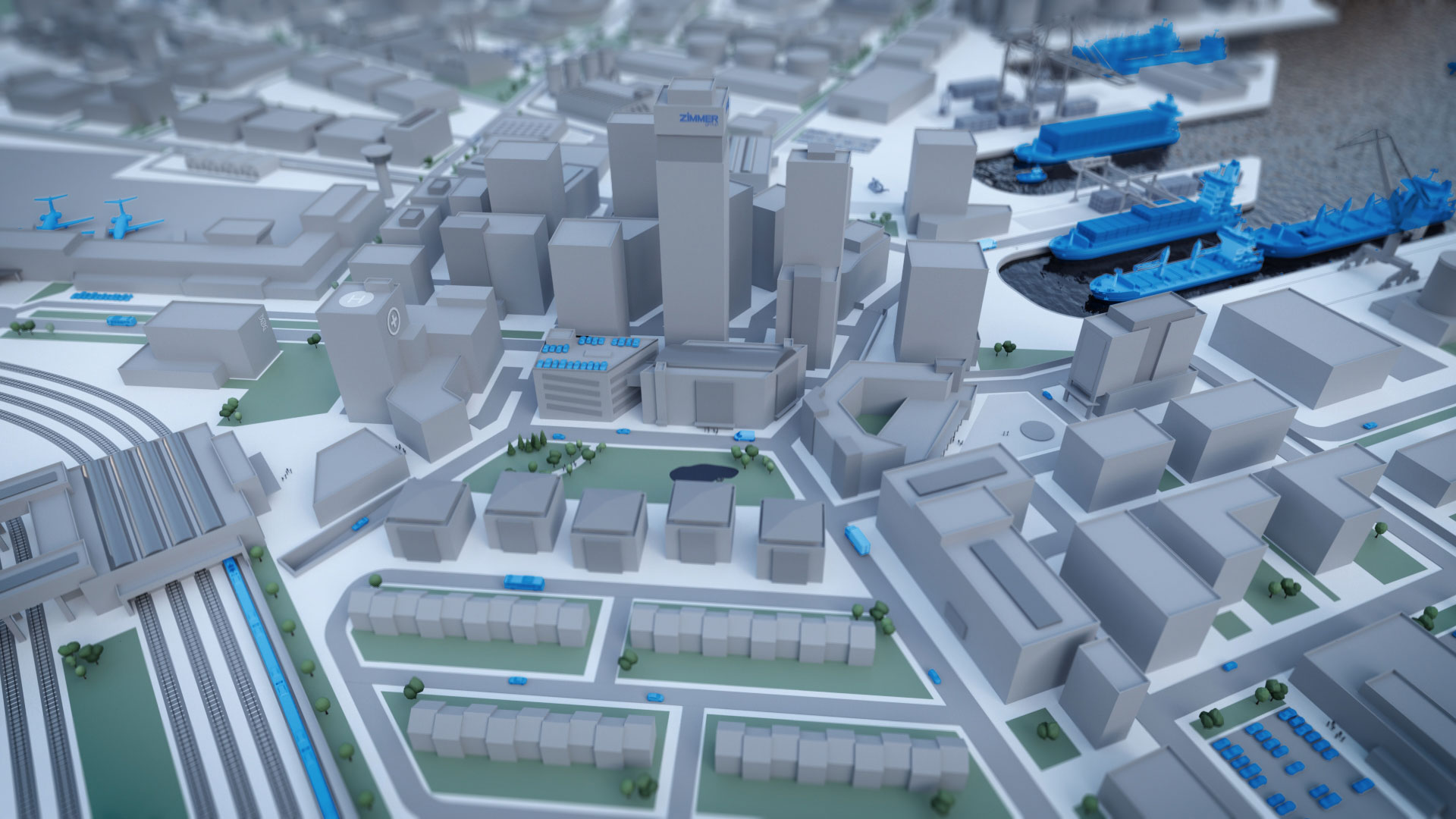

Automation technology for cars, airplanes and the like

From planning, design and implementation to commissioning, maintenance and on-site service: As a leading global manufacturer of automation, machine and damping components and an expert in process technology, we are very familiar with the requirements and processes of the automotive, two and three wheeler, railway vehicle, aviation and shipping industries. Our products stand out thanks to their quality and durability and therefore meet the high standards of the mobility industry. A broad product portfolio of handling technology components, robotics, damping technology, clamping and braking technology, machine tooling technology and industrial communication as well as system solutions such as mobile robotics or gripping systems make us an important partner for numerous well-known companies.

Would you like to find out more about how we can support you? We look forward to continued successful collaboration with you!

Components for the production of cars, airplanes and the like

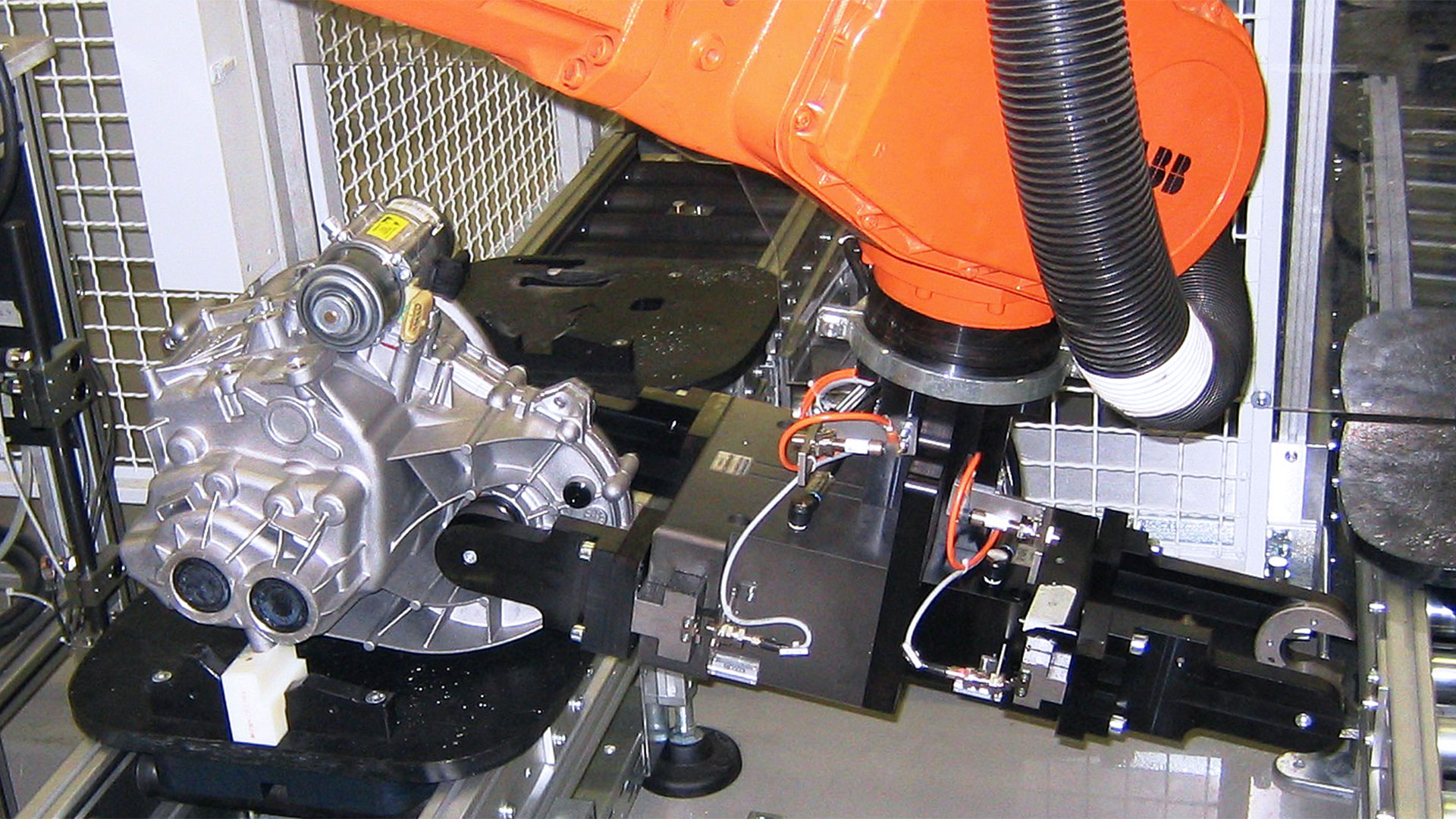

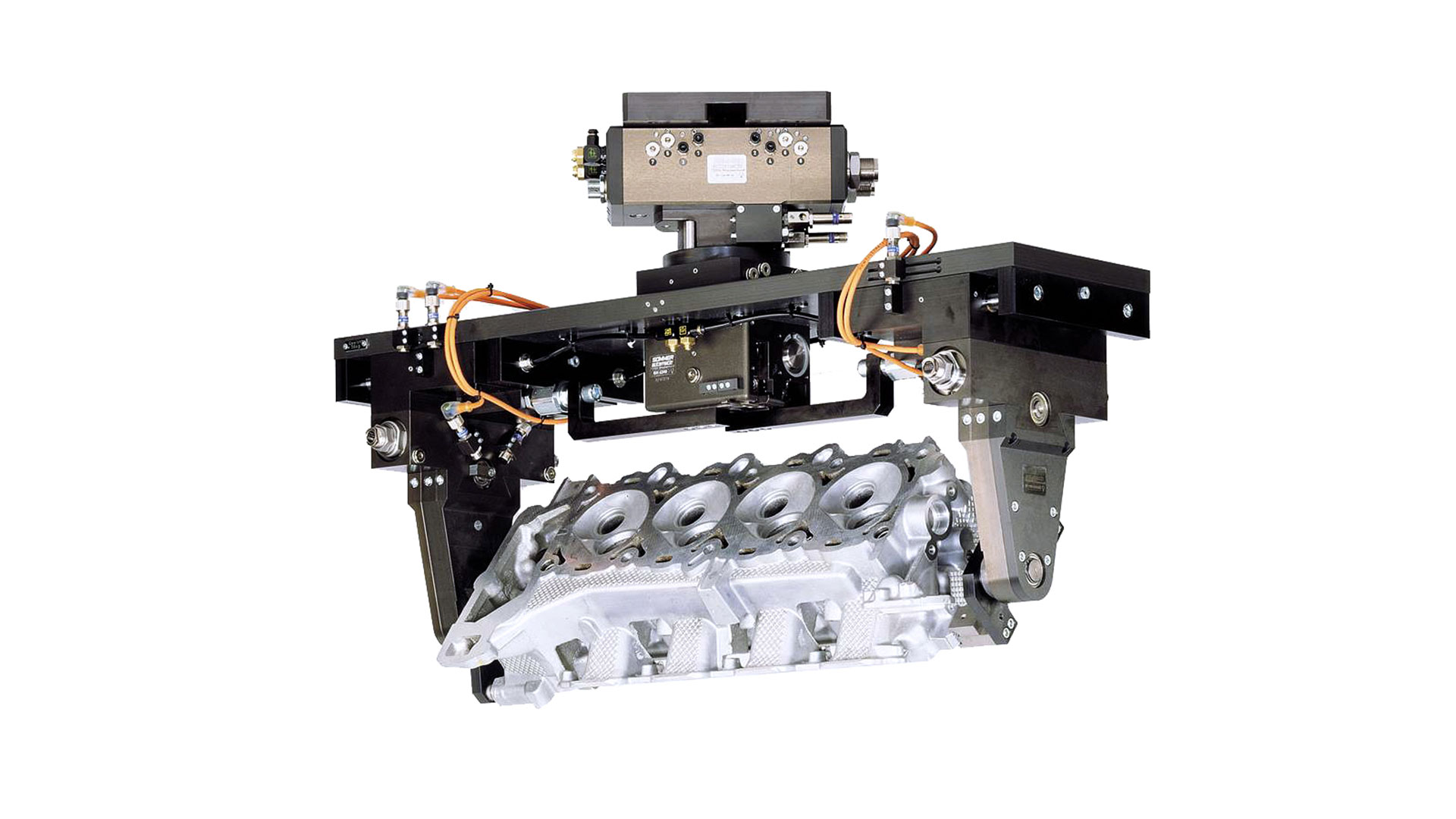

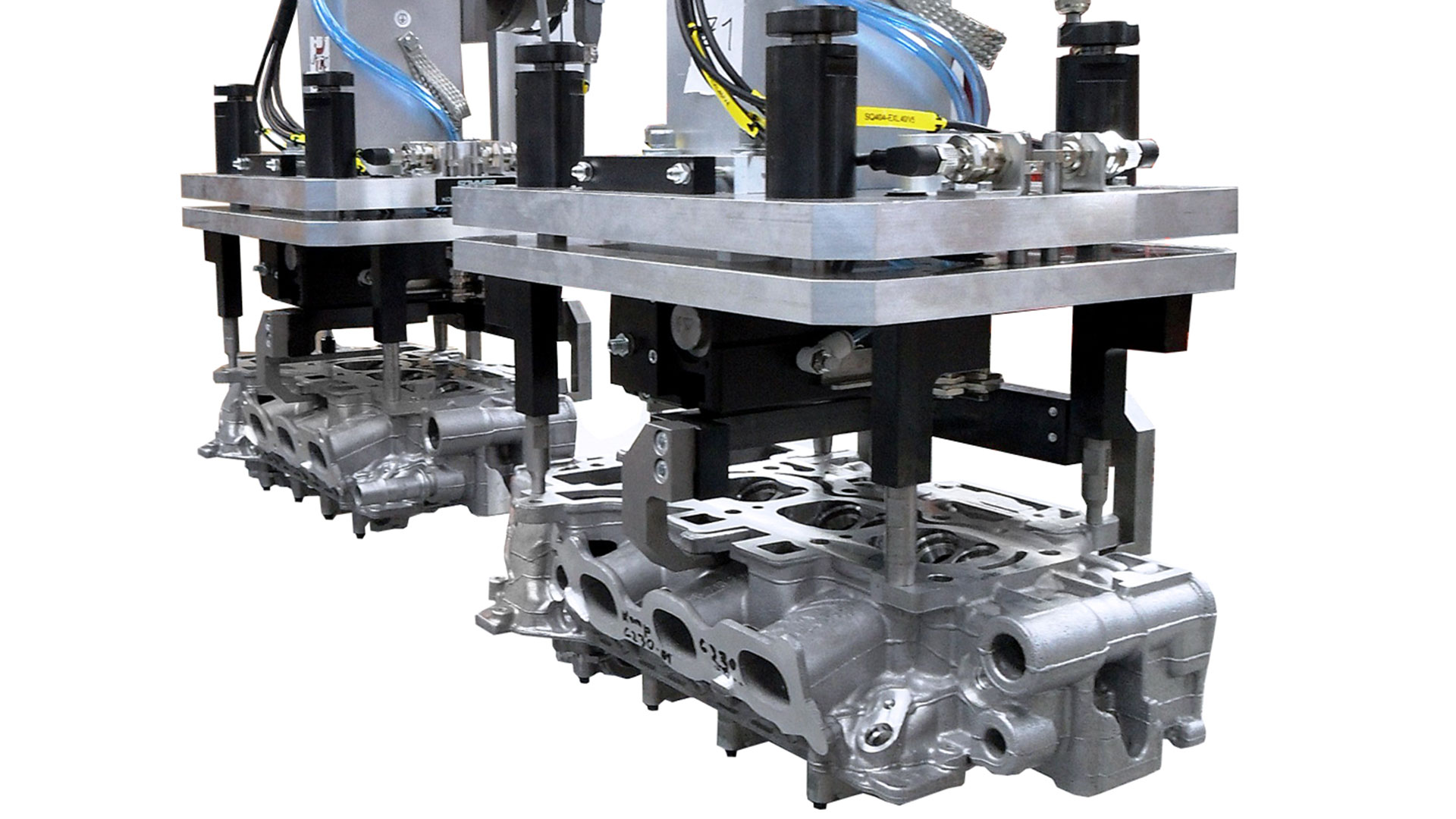

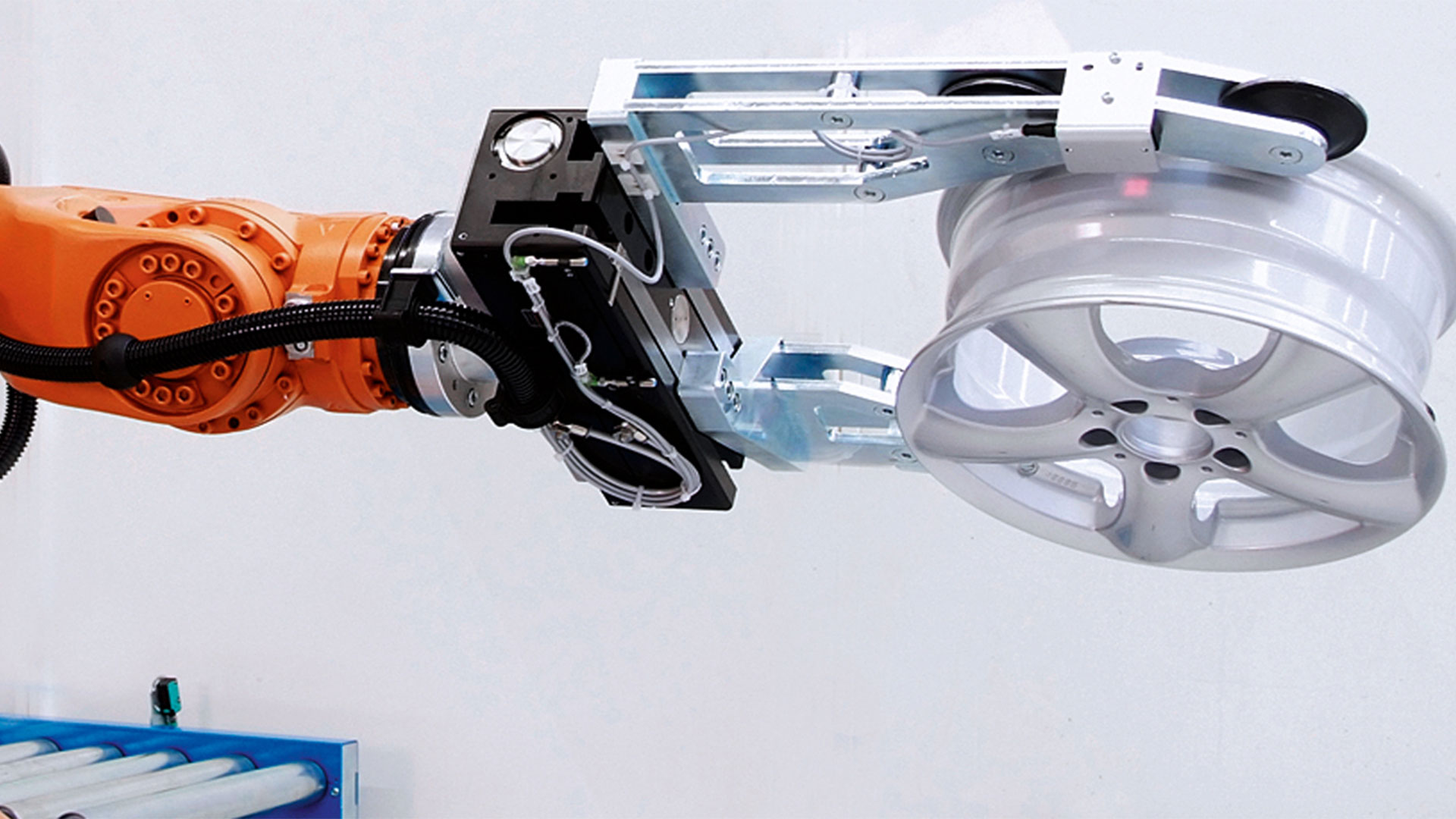

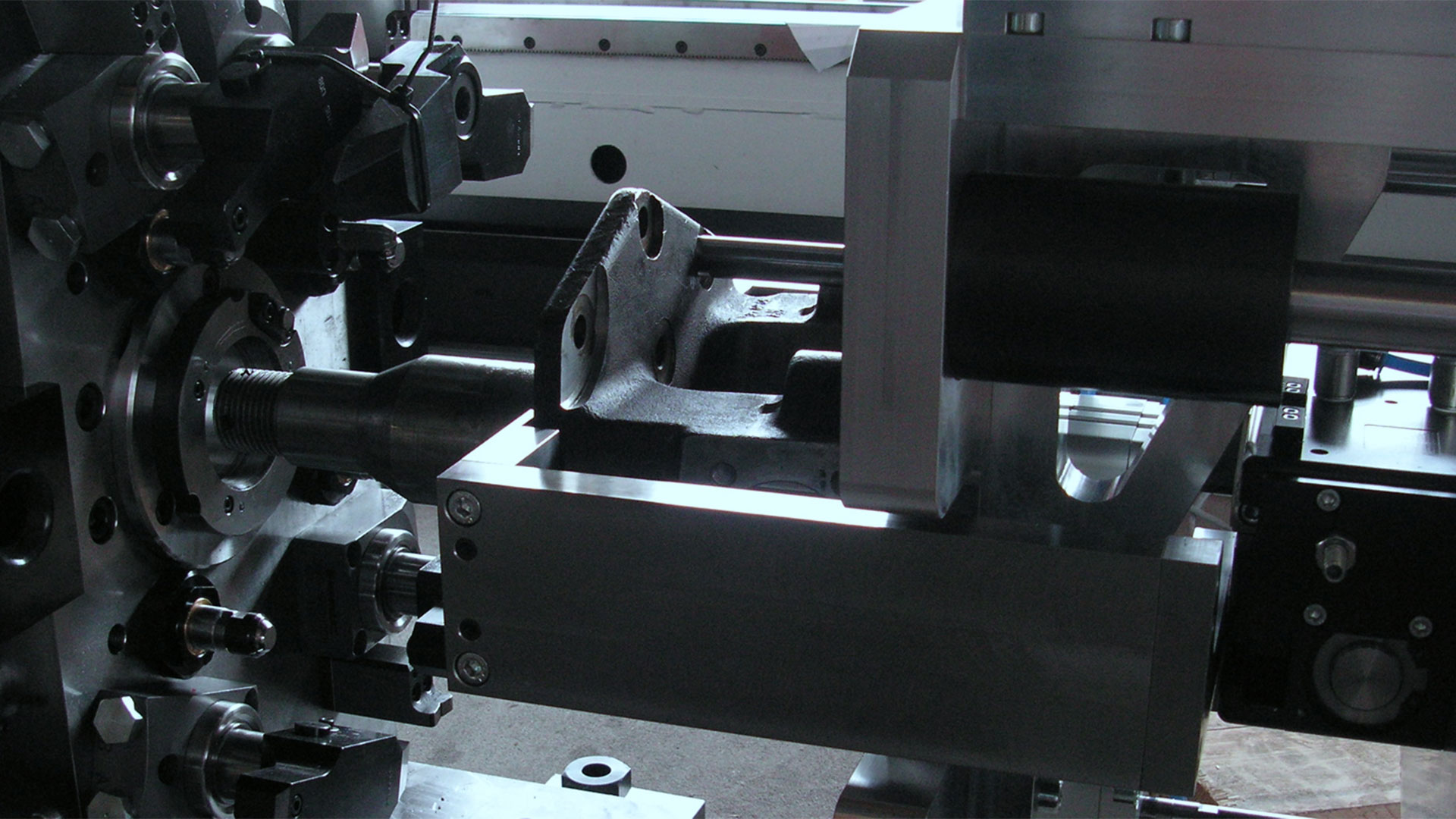

System solutions for mobility

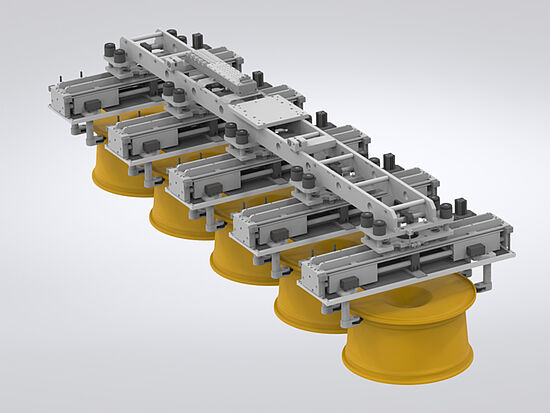

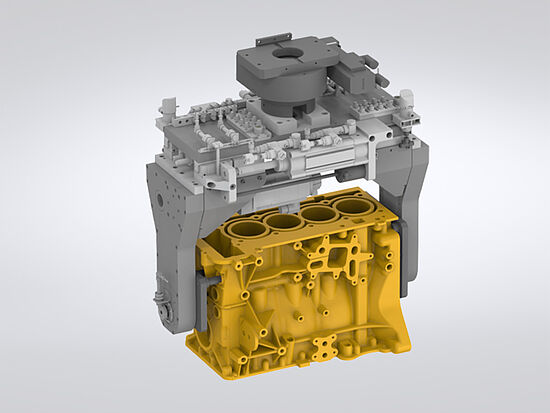

As the KNOW-HOW FACTORY, the Zimmer Group combines various technology areas such as handling, robotics, vacuum, machining, damping and clamping and braking technology under one roof and develops customized solutions for automation tasks worldwide in the age of digital transformation. We draw on a wealth of experience in the mobility market and create system solutions for individual challenges as well as industry standards.

FAQ – frequently asked questions and answers

With an extensive and innovative portfolio, the Zimmer Group unites six technology areas under one roof:

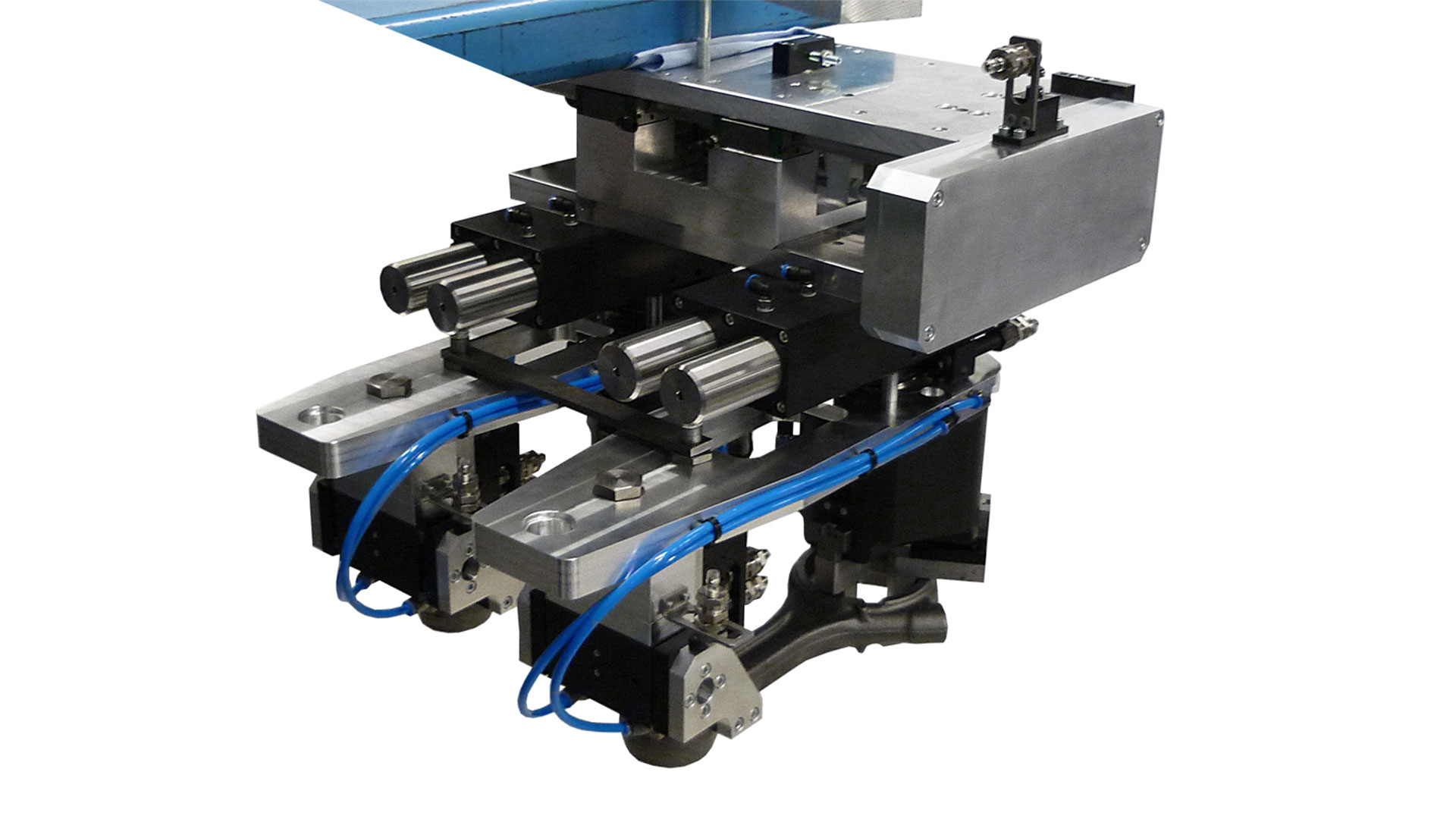

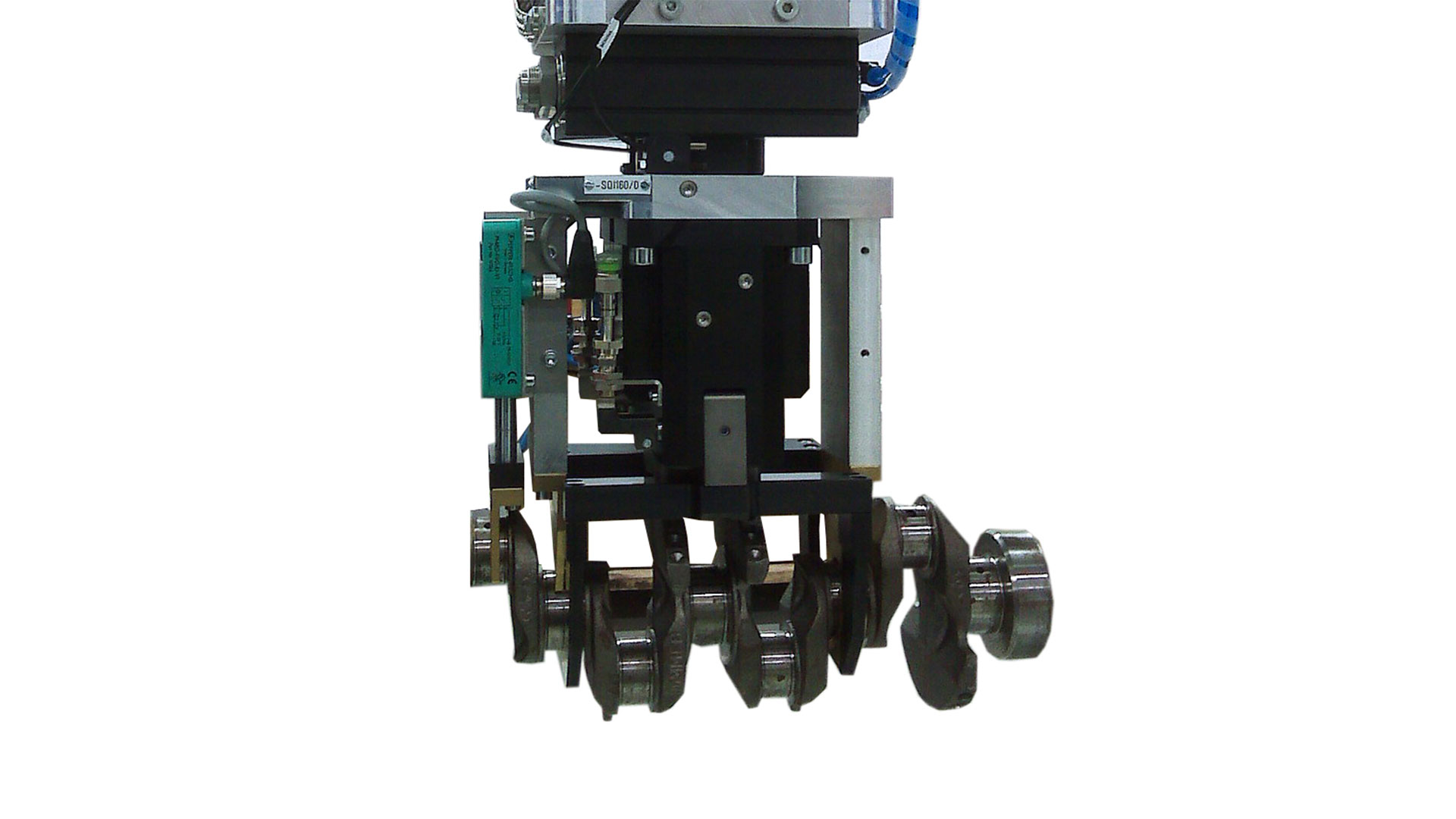

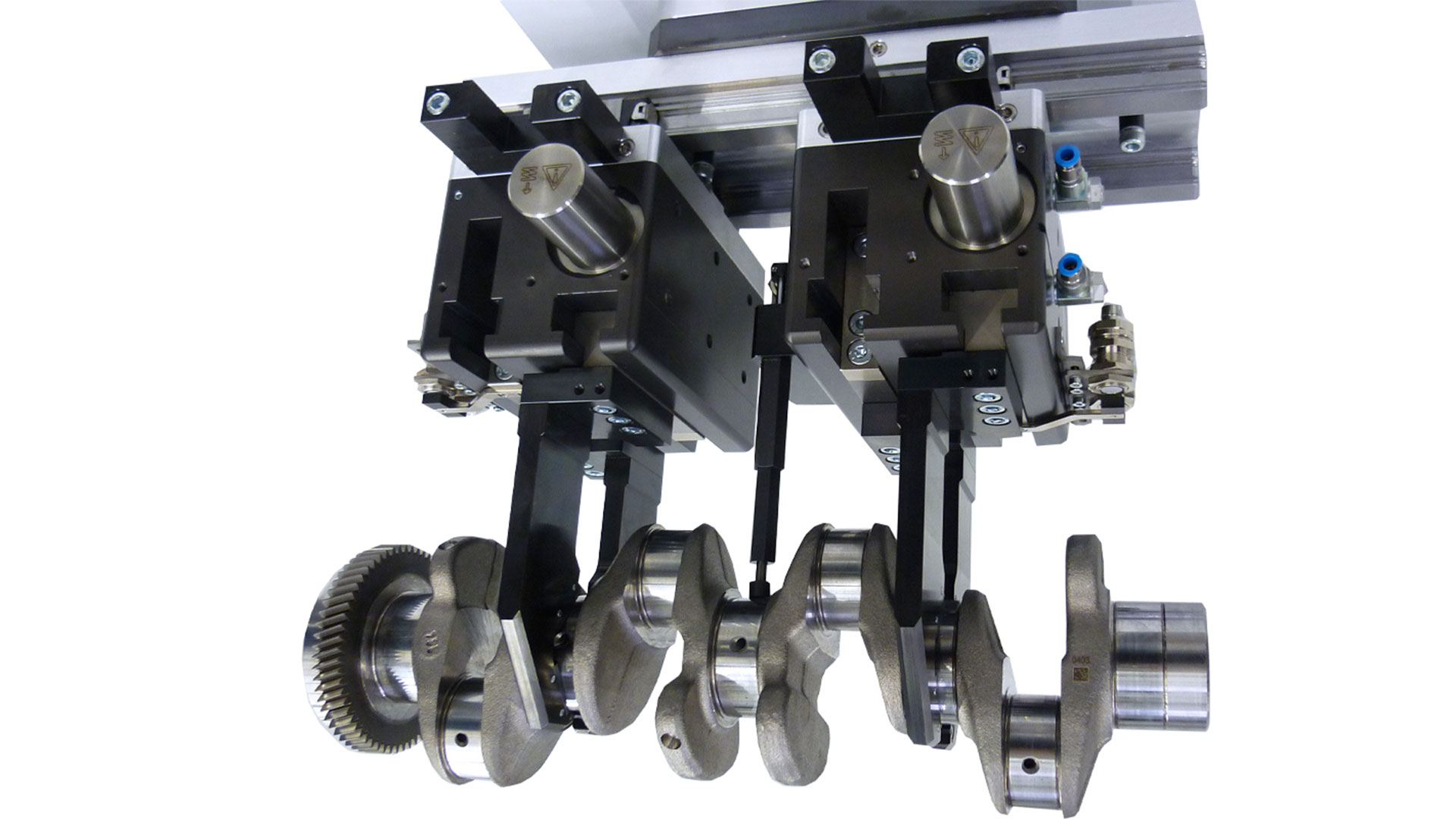

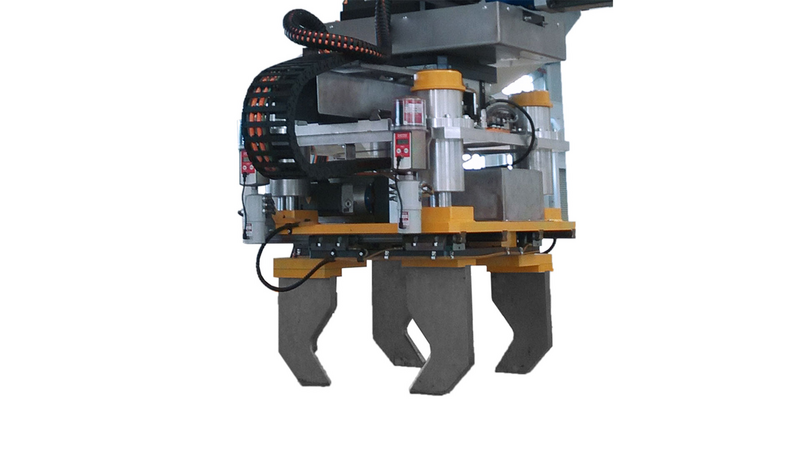

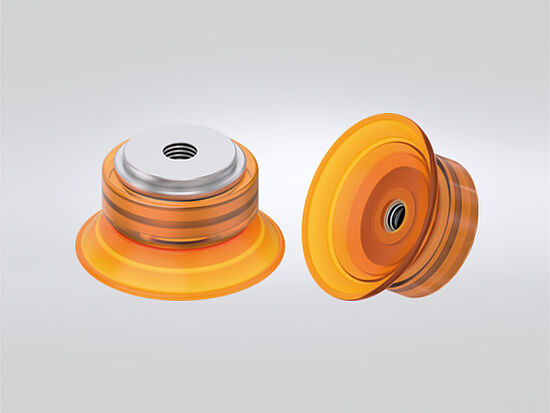

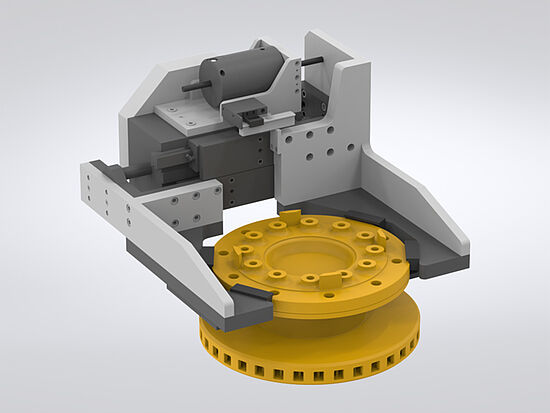

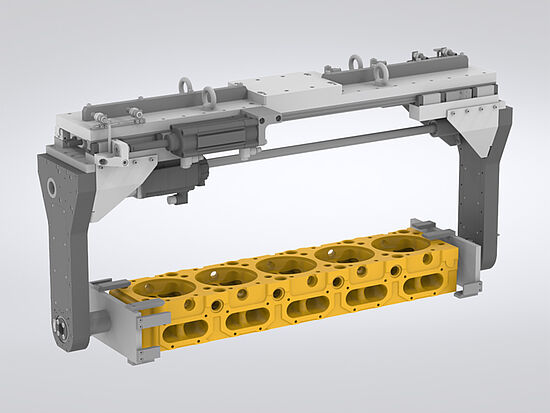

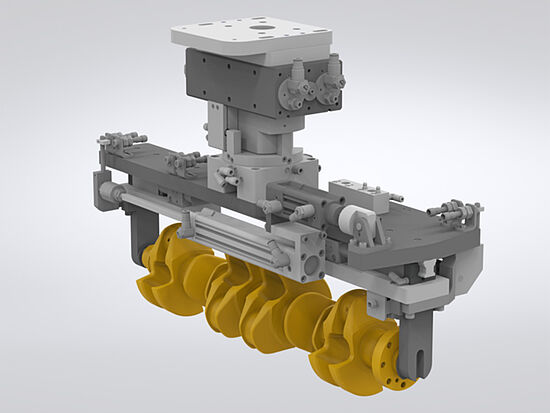

- Handling technology: Components such as swivel units, grippers and robot accessories as standard or semi-standard solutions.

- Damping technology: Industrial and soft close shock absorbers for safely decelerating and braking all types of movements.

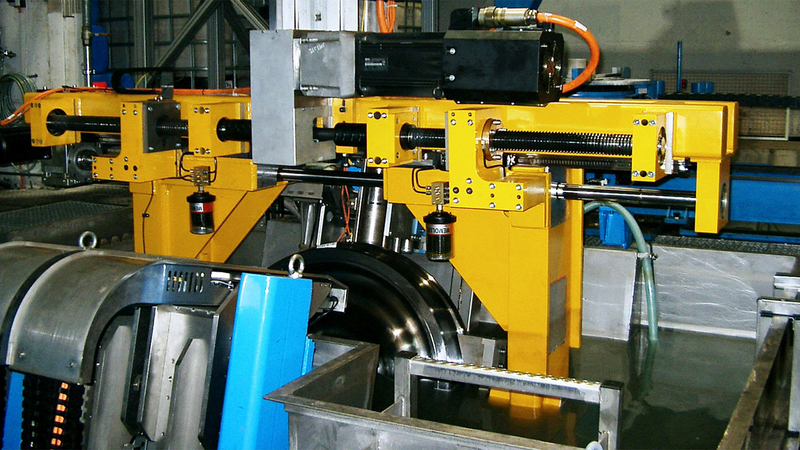

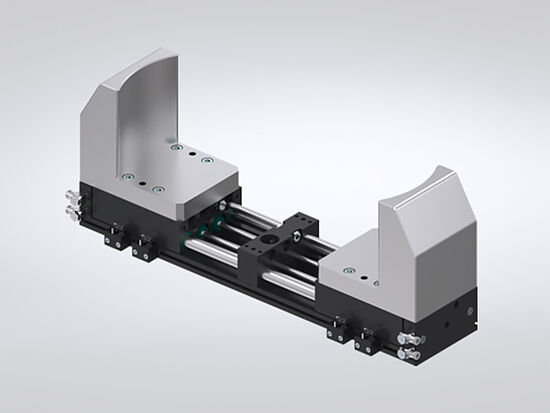

- Machine tooling technology: Single components such as motor spindles, zero-point clamping and transport systems.

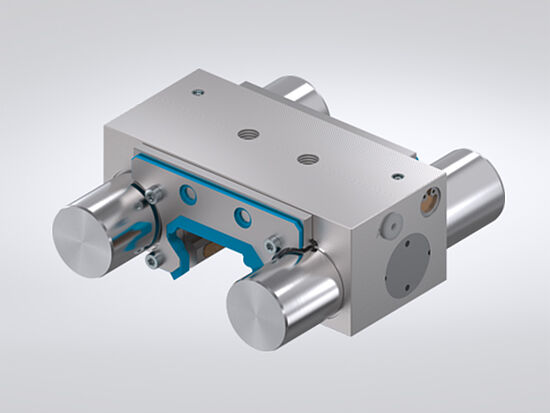

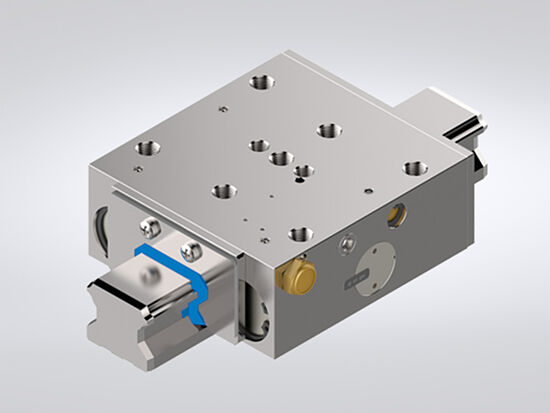

- Clamping and breaking technology: Clamping and braking elements for positioning, holding and braking for a wide range of applications.

- System technology: Customer-specific solutions combined from all technology areas.

- Process technology: Economic series production of products made from metal, plastic or elastomers.

There are also software services that make it easier for your production to take the step towards the smart factory. Digital Services are not just an additional customer service; they are conscious digital and technological enhancements to our products in order to meet the increasing demands of the global market. With our individual solutions, we are an important partner for numerous well-known companies from various areas of the mobility sector.

Automation solutions can help companies regardless of their size in the mobility industry to increase the efficiency and productivity of their production processes, improve the quality of their products and increase the sustainability of their mobility solutions. This includes tasks such as assembly, painting, quality control and packaging. We offer solutions for small and medium-sized companies, but are also an automation partner in plant engineering. Whether and which solution is the right one for you depends on your application and the respective framework conditions, which we will be happy to examine and analyze together with you.

Zimmer Group products help you to increase the efficiency and productivity of your production processes, improve the quality of your products and increase safety for the user and the machine – while always keeping an eye on sustainability and environmental compatibility.

Are you looking for a specific product or would you like specific advice on an application? With our extensive sales network at numerous locations worldwide, we are always there for you personally. Get in touch with us right now!