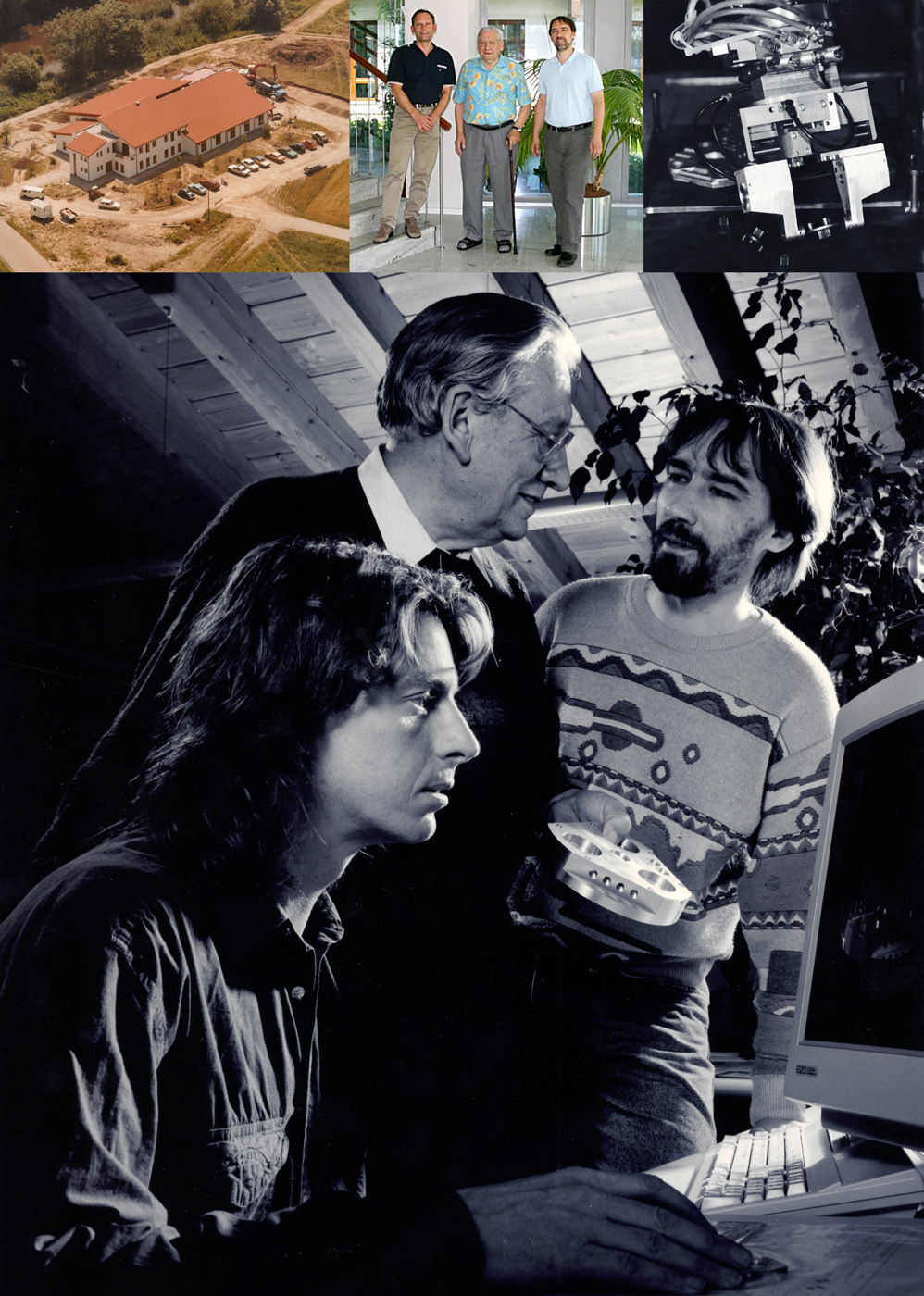

1980 - Foundation of the owner-managed family business in Rheinau-Freistett. The former garage business quickly becomes a high-tech company.

1982 - First automation components are produced

1986- In addition to a small range of standard grippers for robots, further product groups such as linear axes, rotary modules and tool changers are created

1987- Zimmer expands and moves into new own rooms

1992 - Zimmer launches a new type of industrial shock absorber with patented spiral groove technology

1994 - Clamping elements for linear guides are developed

1996 - A new development centre is created

1998 - First customer-specific automation solution

1982

FIRST STANDARDIZED GRIPPER

From a cowshed to a global player – this is how the Zimmer Group‘s success story can be described in short words. In 1980, Günther Zimmer, who became interested in technical processes early on – out of necessity – in order to finance his own agricultural business, founded the company Zimmer Technische Werkstätten.

In an old converted cowshed in Rheinau - Freistett, he, his father and his brother Martin are tinkering with a standardised gripper that facilitates manufacturing processes in industry and can be used in many different ways. This idea led to the breakthrough and laid the foundation for the international success of the later Zimmer Group.

1992

SHOCK ABSORBER WITH SPIRAL GROOVE TECHNOLOGY

With the industrial shock absorbers of the PowerStop family, further exclamation points were set in product development. The PowerStop dampers, which were launched in 1992, owe their impressive properties to a flash of inspiration from their father. When the Zimmer Group‘s tinkerer was confronted with the question of how to eliminate the disadvantages of conventional industrial shock absorbers with throttle holes, he came up with the spiral groove technology, which defines the required throttling of an oil flow in a new way.

This clever technology, which has since been used in PowerStop shock absorbers, outshines all competitor products in terms of low-vibration damping of moving masses and maximum energy absorption in the smallest installation space.

1994

FIRST CLAMPING ELEMENT FOR PROFILE RAILS

In 1994, the young but already enormously grown company launched the first clamping elements for profiled rail guides on the market with the hydraulic clamping element series LKH and the pneumatic variant LK with integrated pressure intensifier. These already achieved high clamping forces and high rigidity in a compact design. As with today‘s elements, the clamping process took place without relative movement, so that no lateral forces were acting on the carriages. Furthermore, the clamping elements were controllable and adjustable and were very easy to install.

Today, the Zimmer Group is the market and technology leader in clamping and braking elements and offers more than 4,000 variants for profile and round rails as well as for a wide range of guide systems from all manufacturers. Regardless of whether they are manually, pneumatically, electrically or hydraulically driven.

1999 - With Sommer-automatic GmbH one of the world‘s leading suppliers of pneumatic and electrical handling components and systems is integrated.

2002 - New construction of the production hall „Im Salmenkopf“

Foundation of the Zimmer GmbH Daempfungssysteme. Today it is one of the leading development partners of the furniture industry. New construction of the sales building at the Ettlingen location.

2007 - Foundation of Zimmer GmbH Kunststofftechnik, which has made an international name for itself with its own toolmaking

and MIM processes.

2009 - New construction of the production facility Werk 2 at

the location „Am Glockenloch“

2013 - Zimmer GmbH Technische Werkstätten and Sommer-automatic GmbH merge to form Zimmer GmbH. The independent companies Zimmer GmbH Kunststofftechnik and Zimmer GmbH Daempfungssysteme as well as Benz GmbH will in future form the Zimmer Group together with Zimmer GmbH. The common goal: everything from one source for the global market. The Zimmer Group sees itself from now on as THE KNOW-HOW FACTORY.

2014 - Expansion of the „Am Glockenloch“ site

2015 - Winner of the Handling Award 2015 for mechatronic gripper

The Wöku GmbH tool construction and plastic injection moulding is integrated

2016 - Second expansion of the „Am Glockenloch“ site

2018 - Winner of 6 RedDot Design Awards and 4 IF Design Awards

2019 - Several times awarded with the German Brand Award, German Innovation Award and German Design Award