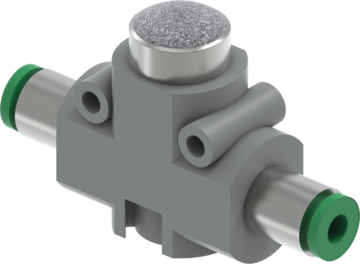

GD10

3-Jaw Concentric Grippers

Series GD

"The flexible"

- Largest stroke in small installation space

You can cover numerous application variants with just one gripper type - Gripper jaws included in the delivery

Reduces your design effort, manufacturing costs and setup time - Smooth stroke configuration

Using the optionally available stroke limit, you can customise the stroke to your application, even stroke sensing is possible

Equipment/Options

10 million maintenance-free cycles (max.)

10 million maintenance-free cycles (max.) IP40

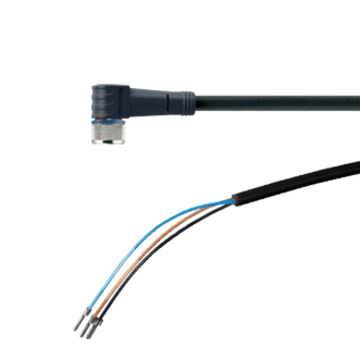

IP40 Inductive sensor

Inductive sensor

Technical Data

| Stroke per jaw | 180 [°] |

| Gripping diameter in closing min. | 5 [mm] |

| Gripping diameter in closing max. | 45 [mm] |

| Gripping diameter in opening min. | 11 [mm] |

| Gripping diameter in opening max. | 51 [mm] |

| Gripping moment in closing | 1 [Nm] |

| Gripping moment in opening | 1 [Nm] |

| Closing time | 0.07 [s] |

| Opening time | 0.07 [s] |

| Repetition accuracy +/- | 0.05 [mm] |

| Operating pressure | 3 ... 8 [bar] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature | +5 ... +60 [°C] |

| Air volume per cycle | 20 [cm³] |

| Approvals | LABS / REACH / RoHS |

| Protection to IEC 60529 | IP40 |

| Weight | 0.22 [kg] |

Benefits in detail

- Gripping movement on rotation

for various workpiece diameters - Robust, lightweight housing

Hard-coated aluminum alloy - Planetary transmission

synchronized the movement of the gripper jaws - Standard pins serve as gripper jaw

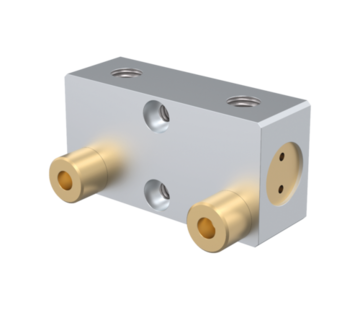

- Mounting and positioning

mounting possible from several sides for versatile positioning - Drive

double-acting pneumatic cylinder - Energy supply

possible radial and axial - Shaft projection

for accessory assembly e.g. sensors