Automation technology for the chemical industry

Our customized automation solutions ensure error-free handling and dosing of your highly sensitive substances. Create a safe working environment for your employees and your plant and set up your smart factory that not only produces intelligently, but also reduces the ecological footprint. With us by your side, you not only master the challenges of the chemical industry, you set new standards. Get off to a flying start in the future of chemistry: automated, efficient, sustainable.

Would you like a personal consultation? We look forward to your inquiry!

Your benefits:

- Individual system solutions: Perfectly tailored to the specific needs of the chemical industry.

- Increase in efficiency: Higher productivity and quality through precise process automation.

- Safety: Advanced technologies and compliance with the required safety standards for occupational safety and the environment.

- Simple integration: Easy connection to existing production infrastructures.

- Sustainability and scalability: Environmentally friendly, future-proof investments with adaptable capacity.

Application examples

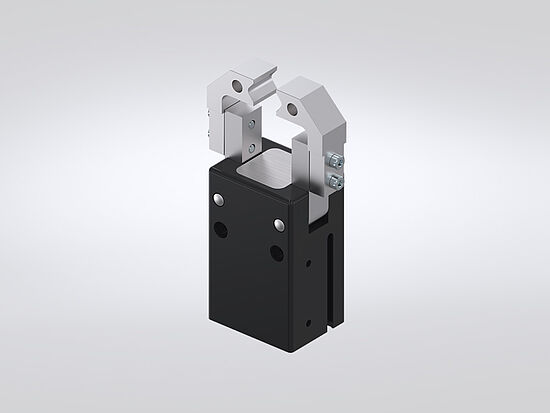

Handling of vials

The GEP2000 standard gripper was fitted for this customer-specific solution. To meet the requirements in the laboratory, the electric gripper features a hygienic design, uses only stainless steel and PEEK and ensures IP65 protection class. The integrated position detection identifies various products and also recognizes any loss.

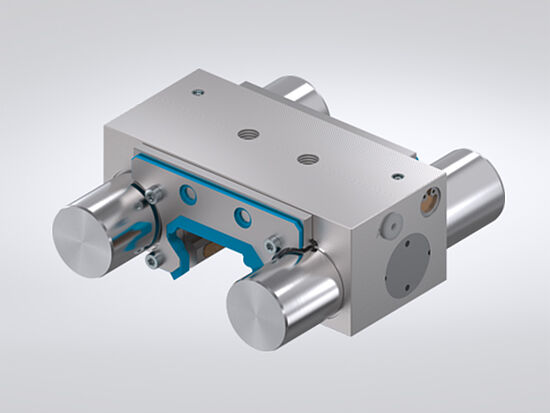

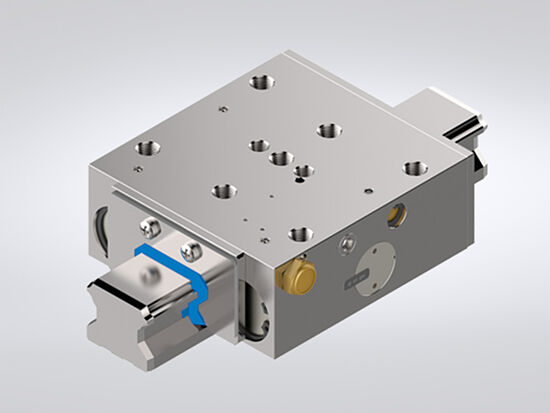

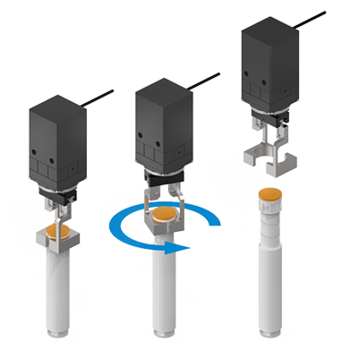

Decapper / recapper

The automated opening and closing of samples is a key requirement in modern chemical plants and laboratories. The combination of rotating and gripping with this customer-specific solution allows it to decap and recap specimen vials. Individually adjustable forces and positionability of the gripper and rotary module ensure maximum flexibility in the application.

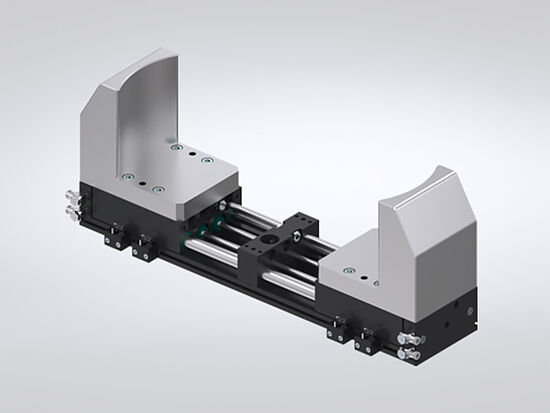

Transport of racks

For handling racks in laboratory automation, an electrically positionable gripper was used. The adapted gripper based on the GEH6000IL series is equipped with a mechanical self-locking mechanism to prevent the loss of the rack in the event of a power failure. Hygienic design, IP54 protection class and the use of stainless steel enable seamless use in laboratories.