MIM technology

METAL INJECTION MOLDING

MIM process

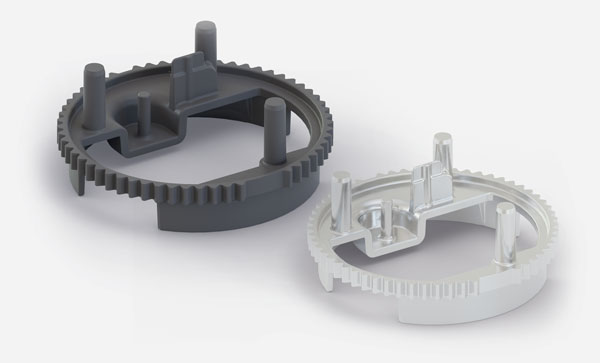

Thanks to the Zimmer Group's metal injection molding process, there are no limits to the production of sophisticated workpieces. Complex shaped series components made of metal often involve a multi-layered production process. The MIM process counteracts this and enables the production of metal parts in almost any shape using injection molding, combining the geometric freedom of plastic injection molding with the strength and wear properties of metals.

As a result, MIM technology offers you a host of appealing advantages:

- Cost-effective series production of metallic workpieces

- Entirely new level of freedom for designing parts

- Combines the advantages of injection molding technology with the outstanding strength and wear characteristics of metals

- Series production of smaller components with weights from 0.3 g to 150 g

- Complex components with a wall thickness down to 0.2 mm

- Ability to implement small and large holes, inner and outer threading, cross holes, undercuts and gear teeth

- Full utilization of the strength properties of the material being used

- Mechanical strength of workpieces equal to conventional manufacturing processes

- Surface treatment using frictional grinding, mirror polishing, sandblasting, passivation, electropolishing or etching

- Coating using burnishing or plating with chrome, copper, nickel, silver or gold

- Avoids production costs and the use of expensive assembly and connection techniques

- Significantly lower costs for complex components

- 25% to 65% less expensive than conventional production processes

- Applicable in a vast assortment of areas: Gearbox parts, watches, jewelry, eyeglass parts, surgical instruments, tweezers, dental braces, small and micro-sized parts for mobile phones, computers or other devices

MIM The process

Feedstock

The starting material for metal injection molding is formed from what is known as the feedstock. This consists of about 60% of the respective metal powder by volume and 40% of a binder by volume, i.e. a blend of polymers and waxes. The homogeneous mixture of all of the components is of critical importance, since that is the only way to ensure optimal processing and uniform product quality in later processes.

Injection molding

The feedstock is processed using conventional injection molding machines the same way as plastic pellets. The binder portion is melted at a high temperature and the highly viscous mass of metal powder and binder is then pressed into the shape of the respective component. The resulting workpieces made of metal powder and binder are called "green parts" and have to be converted into purely metallic components in the subsequent processes.

Debinding

In the debinding step, the majority of the binder is removed from the green parts. This normally happens by dissolving the binder components using a solvent or a catalytic reaction. What remains is a porous component held together by the remaining binder. These are then called "brown parts". The remaining binder is then removed in a furnace. This means that the remaining binder is vaporized out of the component at a high temperature between 400 °C and 900 °C. At the same time, the metal particles start to bind together by forming what are known as sinter necks. They give the component sufficient stability for the subsequent sintering step.

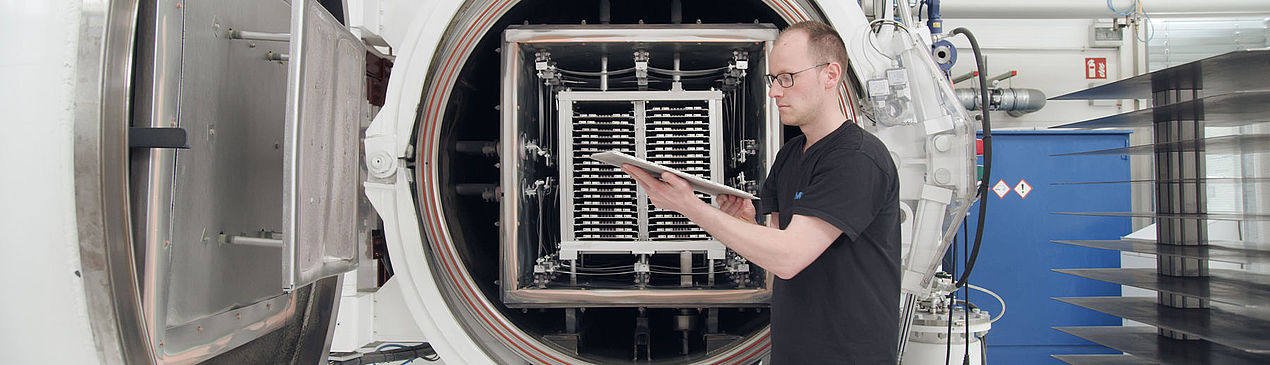

Sintering

The last process step, sintering, closes the pores left over by the binder. The components are compressed at high temperatures, usually over 1,000 °C. The respective temperature profile in the sinter furnace heavily depends on the material and the component geometry. As a result, this process step has to be carefully adapted and developed for each component geometry and each material. It is this care that ensures your components have optimal quality throughout their life cycle.

Request form

Metal injection molding - MIM

Times for offer - market requirements

- Plastic parts - within 3 working days*

- MIM parts - within 3 working days*

- Injection moulding tools (plastic/MIM) - within 3 working days*

- Tool changes - within 3 working days*

- Services (milling, turning, eroding) - within 3 working days*

*Prerequisite: Component design is completed or released.