Pharmaceutical industry

FROM NUMEROUS STANDARD VARIANTS TO THE INDIVIDUAL SOLUTION

Pharmaceutical industry, laboratory automation, medical technology

Zimmer Group stands at the forefront of globally leading manufacturers of components for automation, machines and furniture damping as well as process technology. Furthermore, with our individual solutions, Zimmer Group is an important partner of numerous well-known companies in the medical and pharmaceutical sectors. Since 1980, Zimmer Group has stood for high innovative strength – "Made in Germany." With leading technological products and a sales network in 125 countries, we support the growth of our customers with long-lasting contributions.

EACH SECTOR HAS ITS OWN REQUIREMENTS

Many industries and sectors have a number of special requirements and a high standard for components. Medical and pharmaceutical technology has unequaled standards for quality, durability and safety. Even today, many standard products from all of our technology areas are capable of mastering many of these challenges.

Cleaning/sterilization

Our hygienic design makes our products very easy to clean.

Resistant surfaces

We guarantee resistance to aggressive cleaning agents (hydrogen peroxide/H202 and many others).

IP protection class

We make it easy to keep dirt and grime away. Our specially sealed products allow intensive cleaning.

Clean room

We comply with the limit values and ensure reduced particle emissions in accordance with GMP and ISO 14644.

Certified lubricants

Our solutions comply with the requirements of FDA regulation 21 CFR 178.3570.

Various materials

We use only approved materials included in the FDA material list.

Any workpiece, any type of automation

Whichever product you are handling, we have the components you need. Is your application complicated? We gladly accept challenges such as this by also offering customer-specific complete system solutions.

Gripping

Exchanging

Clamping

Swiveling

Protecting

Braking

Rotating

Damping

Transporting

Want a sample?

The reference cards provide one of our many examples from the medical and pharmaceutical field and the corresponding product series.

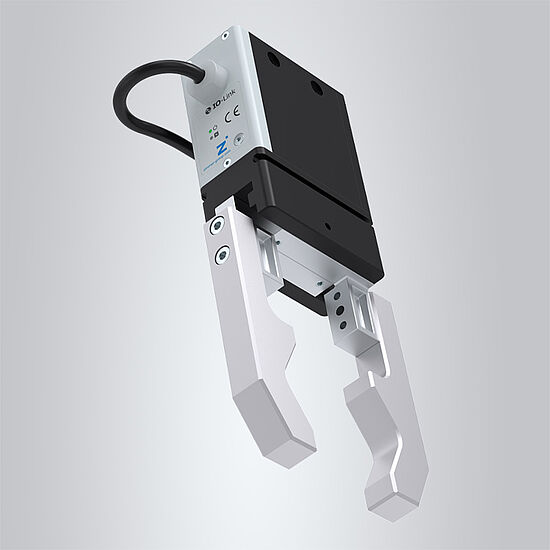

2-JAW PARALLEL GRIPPERS

GEP2000 SERIES

The electric compact one

The proven GEP2000 series includes electric small part grippers for medical and laboratory automation applications that feature free positioning and workpiece loss detection, among other features. A key characteristic of the grippers is the self-locking mechanism, which ensures a secure hold on the workpiece (e.g. an infectious specimen vial) even in the event of a power drop or emergency stop.

10 million maintenance-free cycles (max.)

Integrated sensing

Mechanical self-locking mechanism

Magnetic field sensor

Adjustable gripping force

IO-Link

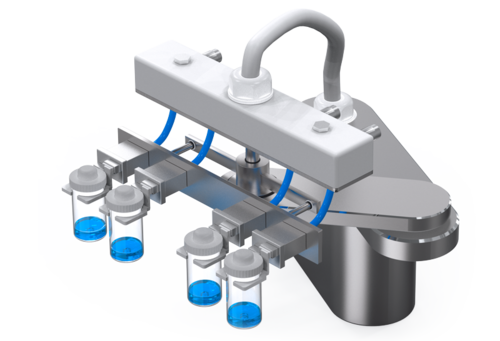

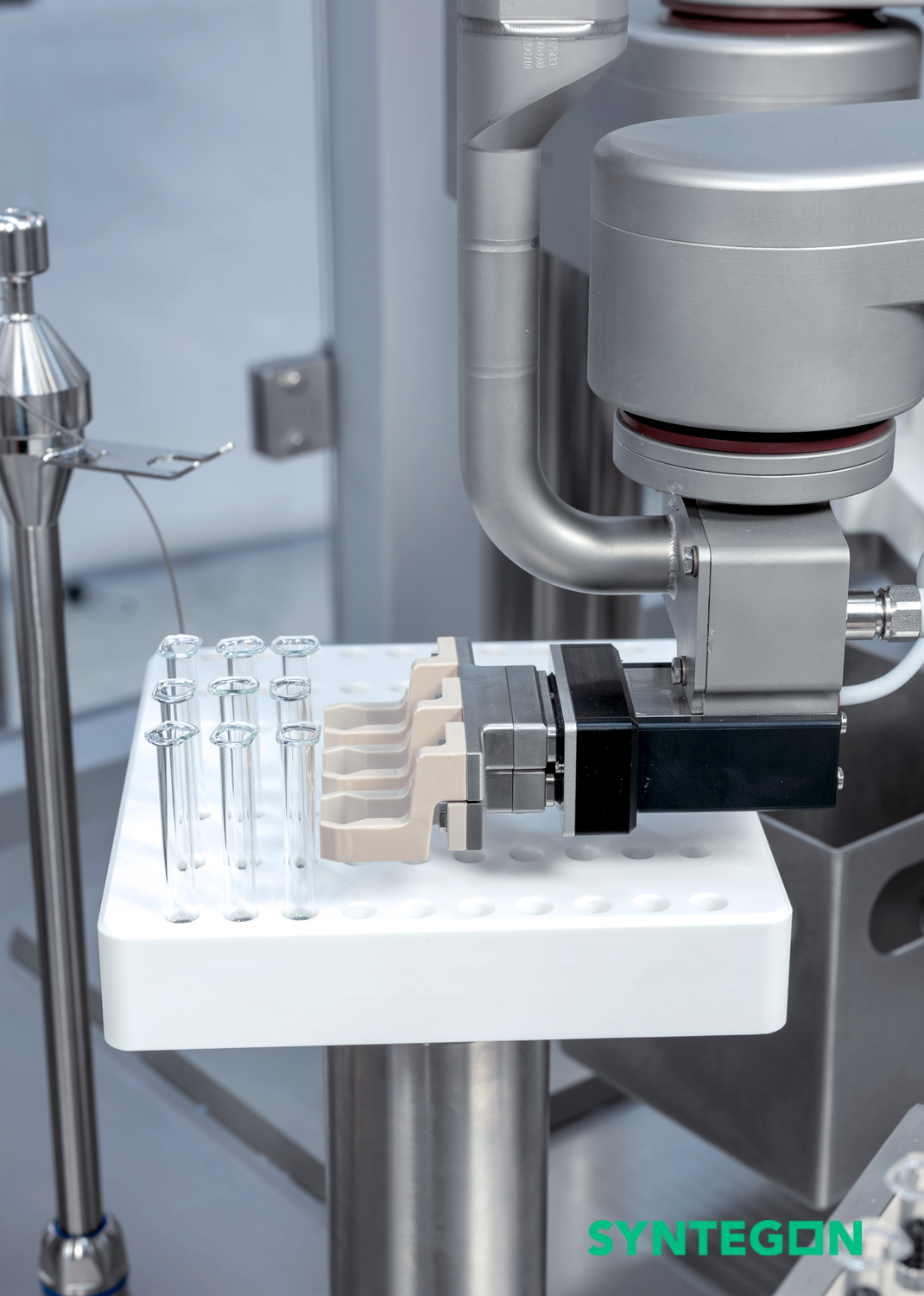

HANDLING OF glass vials

HANDLING TECHNOLOGY

Position detection identifies loss

The customer-specific electric gripper is used to transport vials and syringes in a filling system. Thanks to the integrated position detection of the gripper, you can detect the various products and identify any potential loss immediately.

Benefits

- Hygienic design: sealed gripping module, axial connection cable

- Housing made of stainless steel, PEEK or PET: external steel parts made of 1.4404, gripper housing made of PET, protector seals made of FKM, other external seals made of silicone

- External parts H2O2-resistant

Hydrogen peroxide-resistant materials

Reduced particle emissions according to GMP

FDA-compliant design

Protection class to IEC 60529

Food-safe H1 greasing

HANDLING OF glass vials

HANDLING TECHNOLOGY

Position detection identifies loss

The customer-specific electric gripper is used to transport vials and syringes in a filling system. Thanks to the integrated position detection of the gripper, you can detect the various products and identify any potential loss immediately.

INFORMATION

Component

Customer-specific solution based on the GEP2000 electric gripper seriesSpecial featuresHygienic design, IP54, media-resistant because of the use of stainless steel and PEEK, stroke lengthened to 11 mm per gripper jaw

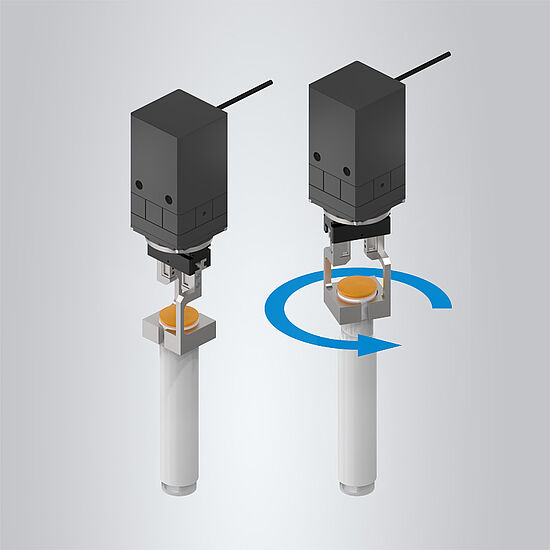

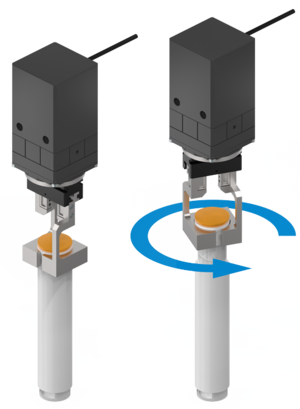

OPENING AND CLOSING SPECIMENS

HANDLING TECHNOLOGY

One component – two functions

This special handling solution features a combination of rotating and gripping that enables it to serve as the decapper and recapper of specimen vials. It is also used for labeling vials or aligning their barcode so that it can be scanned in.

INFORMATION

Component

Customer-specific solution based on the GEP2000 gripper seriesSpecial features

Adjustable forces and positionability of the gripper and rotary module

2-JAW PARALLEL GRIPPERS

MGP800 SERIES

High performance

For handling reagent glasses and other small parts, Zimmer Group offers you best-in-class performance with MGP800 series pneumatic grippers. Experience their ruggedness, durability and performance firsthand and take a closer look at our smallest models. The most lightweight is a mere 0.008 kg.

10 million maintenance-free cycles (max.)

Magnetic field sensor

Spring closing C

IP40

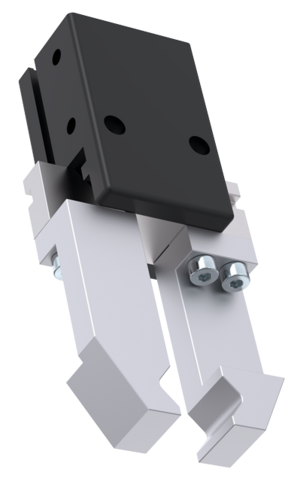

TRANSPORT OF INSULIN-STICKS

HANDLING TECHNOLOGY

Standard grippers for individual solutions

Insulin sticks are transported in a production plant using a pneumatic standard gripper of the MGP800 series. The small design of the grippers enabled the pitch to be reduced to a minimum, thus allowing multiple grippers to be positioned next to each other.

INFORMATION

Component

MGP800 seriesSpecial features

Use of standard components makes adaptations unnecessary

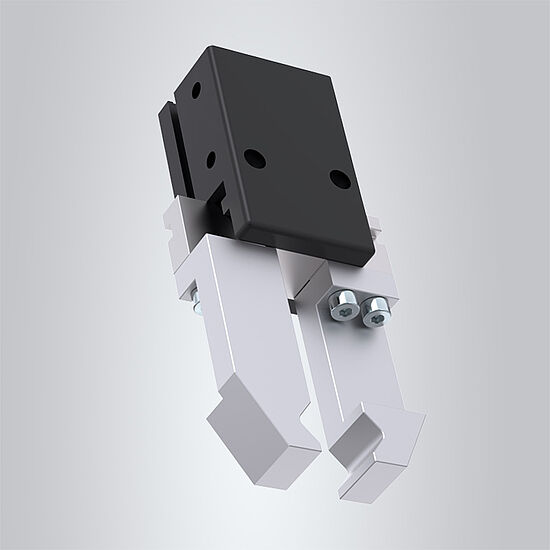

2-JAW PARALLEL GRIPPERS

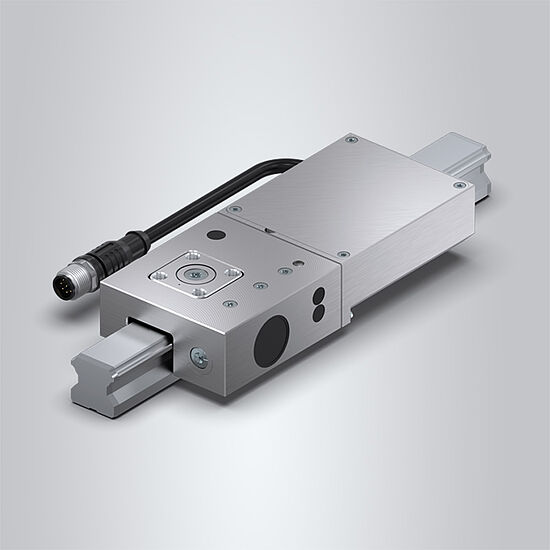

GEH6000IL SERIES

Highest performance

The GEH6000IL series electric grippers with long stroke are equipped with a servo drive with integrated controller. The brushless drive technology guarantees not only individual force adjustment, but also control of the position and speed. Because laboratory automation is characterized by work with fragile glass and plastic, the grippers also have a mechanical self-locking mechanism, which prevents a vial from falling in the event of a power failure.

Positionable

Integrated sensing

IP54

Mechanical self-locking mechanism

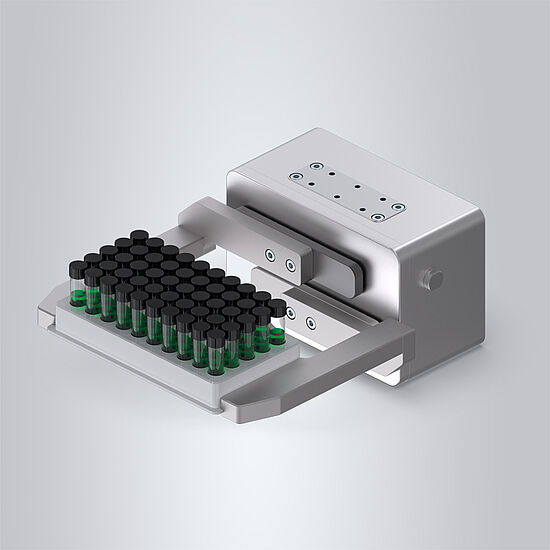

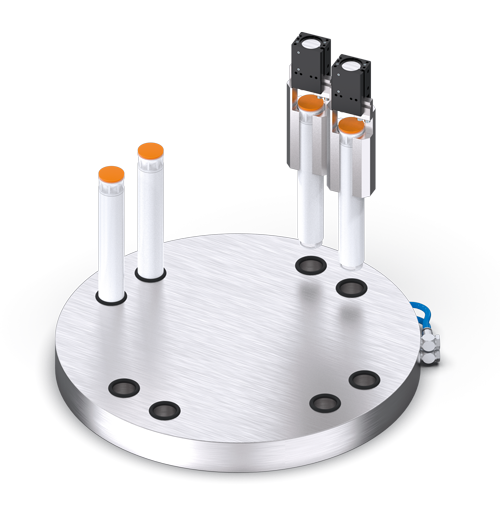

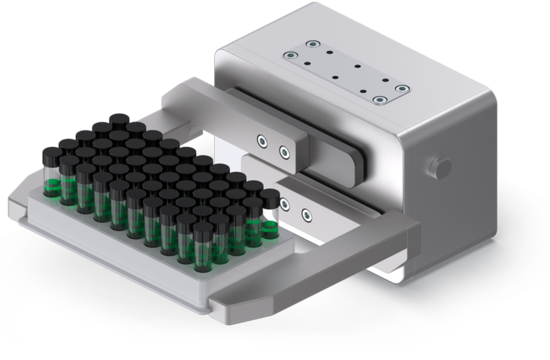

REAGENT GLASS HANDLING

HANDLING TECHNOLOGY

The best choice for safety and reliability

A positionable electric gripper is used for the highly sensitive transport of racks in laboratory automation. The adapted gripper based on the proven GEH6000IL series is equipped with a mechanical self-locking mechanism to prevent opening and thus the loss of the rack in the event of a power failure.

INFORMATION

Component

Customer-specific solution based on the GEH6000IL electric gripper seriesSpecial features

Hygienic design, IP54, media-resistant because of the use of stainless steel

HANDLING OF glass vials

HANDLING TECHNOLOGY

Position detection identifies loss

The customer-specific electric gripper is used to transport vials and syringes in a filling system. Thanks to the integrated position detection of the gripper, you can detect the various products and identify any potential loss immediately.

Sie haben Fragen oder selbst eine Anwendung, für die Sie einen Endeffektor mit spezifischen Features benötigen? Wir beraten Sie gern individuell. Nehmen Sie jetzt Kontakt mit uns auf!

Benefits

- Emergency release possible from outside

- Hydrogen peroxide resistant: Housing made of PET, external steel parts made of 1.4404 or 1.4305, protector seals made of FKM

- Protector seal lubricated with cleanroom grease

- Hygienic design

- Electronics module IP 65

Hydrogen peroxide-resistant materials

Reduced particle emissions according to GMP

FDA-compliant design

Protection class to IEC 60529

Food-safe H1 greasing

Cleanroom class 3 according to DIN EN ISO 14644-1

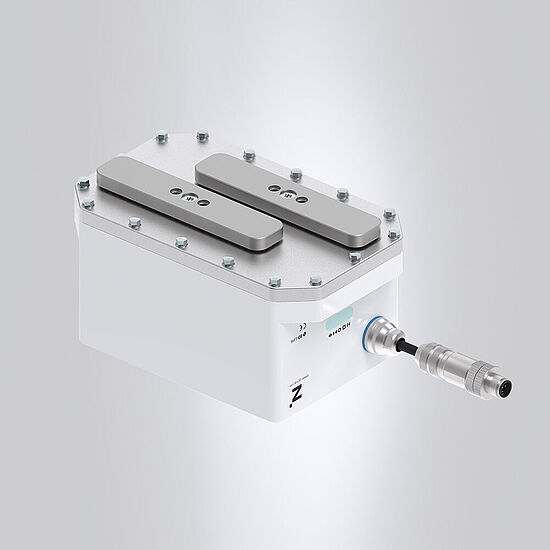

ELECTRIC CLAMPING ELEMENTS

LKE SERIES

Fast, efficient, flexible

The fast electric clamping elements are notable primarily because of their integrated status query, which is output via digital status signals. The kinematics are supplied by means of an eccentric shaft with a mechanical self-locking mechanism. Based on the self-locking functional principle, when closed, the full holding force is sustained in the event of a power drop or while in a de-energized state, ensuring accurate positioning.

INFORMATION

Energy efficient (bistable)

Integrated electronics

Flexible cable outlet

Available for all common profile rail guides

Emergency actuation

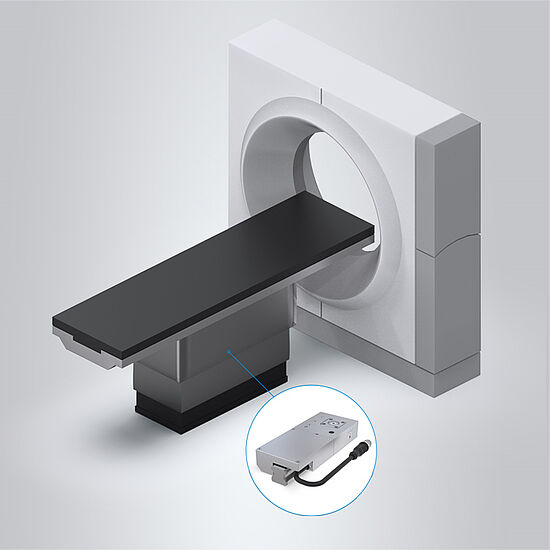

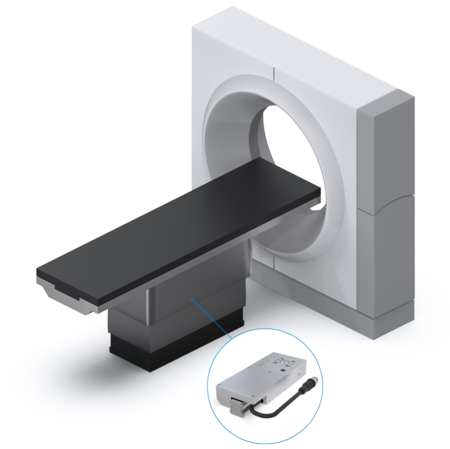

FASTENING OPERATING ROOM TABLES

Linear technology

De-energized clamping with status query

An electric clamping element is used to secure a patient table in place. The element features de-energized clamping and an integrated status query. In case of a power failure, the element can be opened manually at any time.

INFORMATION

Component

LKE electric clamping elementSpecial features

Securing operating room tables in place

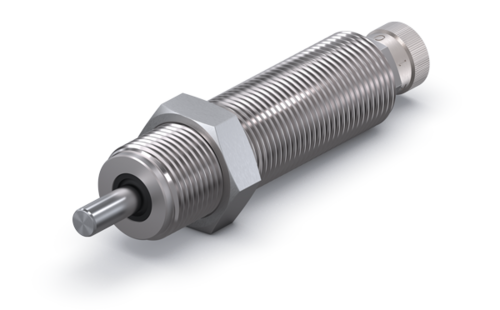

INDUSTRIAL SHOCK ABSORBERS

POWERSTOP PRODUCT FAMILY

Perfected for industry and medicine

The unique spiral groove technology is a defining feature of PowerStop industrial shock absorbers. In contrast with conventional industrial shock absorbers with throttle bores, the constantly tapering spiral groove causes precise, low-vibration damping absorption. They achieve maximum energy absorption with the smallest installation space through optimal utilization.

INFORMATION

Low-vibration damping

Bio oil

Hydrostatic piston guide

Stainless steel

Integrated oil reserve

Optimal protection can be selected

DAMPING PROSTHESES

Damping technology

Damping for greater comfort

Special shock absorbers (based on the PowerStop series) are used in prosthetic knee and hip joints for damping in the swing and standing phase. The dampers can be adjusted individually in the push and pull directions. The characteristic curve can be adapted to the movement sequences in the process. This enables high energy absorption in the smallest space.

INFORMATION

Component

Special shock absorbers (PowerStop product family)Special features

Individual adjustment and high energy absorption