Innovations from the Zimmer Group

Innovations from our technology areas

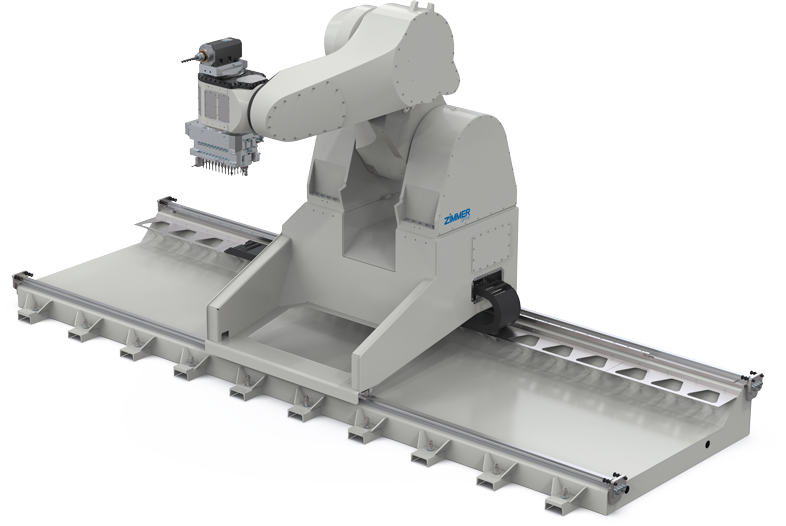

Woodworking

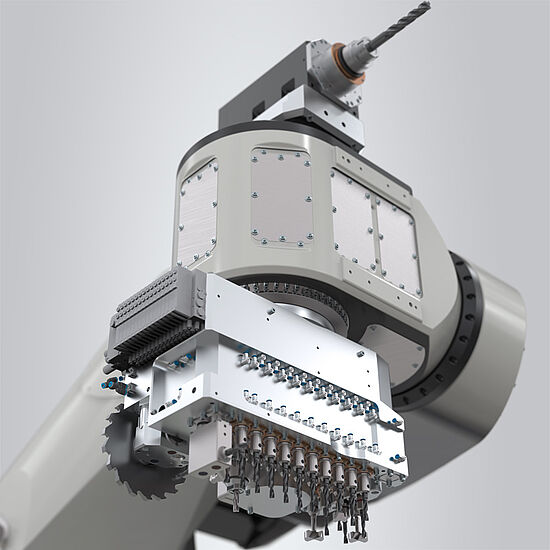

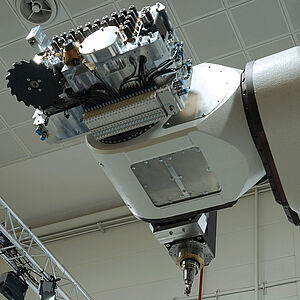

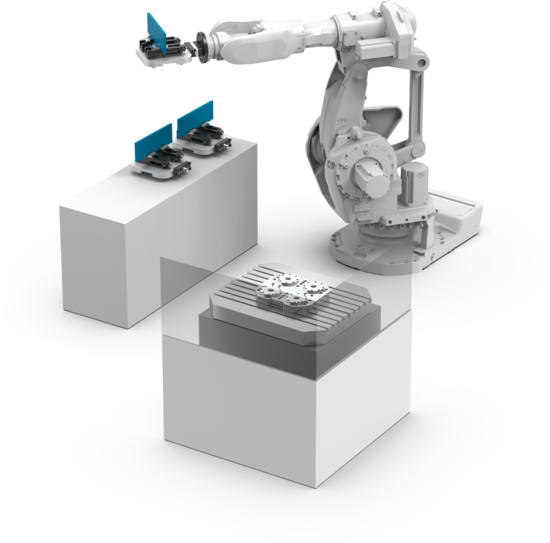

Raptor

RAPTOR is the latest development from the Zimmer Group. It can replicate a wide range of woodworking tasks – such as nesting, milling, pre-assembly and parts handling – using only one machine. This woodworking robot celebrated its premiere at this year's LIGNA in Hanover, the world's leading expo for woodworking and wood processing .

PRODUCT ENHANCEMENT

GEP2000 PROTECTOR VERSION

For increased hygiene requirements

The most successful electric small-part grippers, the GEP2000 series are getting a product upgrade with the new protector version. The cleanroom class 2 certified GEP2000 is ideally suited for use under increased hygiene requirements and in cleanrooms thanks to low particle emissions. It comes with wipers on the top cover, the gripper has an enhanced protection class and is therefore sealed in accordance with IP54. Because it is lubricated with food-grade H1 grease and equipped with sealed guides, it is an optimal fit for use in the food industry. In addition, it also has optimized corrosion protection and is very easy to clean due to the cover and screws made out of stainless steel. Compared to grippers without a protector, the new version has an enlarged stroke of 10 mm per gripper jaw, which can be increased to 20 mm with other installation sizes.

| Technical data | ||||

|---|---|---|---|---|

| Order no. | GEP2006IL-43-B | GEP2006IO-45 | GEP2010IL-43-B | GEP2010IO-45-B |

| Control | IO-Link | I/O | IO-Link | I/O |

| Positionable | Yes | Yes | ||

| Integrated position sensing | via process data | Analog 0 to 10V | via process data | Analog 0 to 10V |

| Gripping force [N] | 145 | 145 | 200 | 200 |

| Stroke per jaw [mm] | 10 | 10 | 13 | 13 |

| Weight [kg] | 0.27 | 0.27 | 0.49 | 49 |

| Technical data | ||||

|---|---|---|---|---|

| Order no. | GEP2013IL-43-B | GEP2013IO-45-B | GEP2016IL-43-B | GEP2016IO-45-B |

| Control | IO-Link | I/O | IO-Link | I/O |

| Positionable | Yes | Yes | ||

| Integrated position sensing | via process data | Analog 0 to 10V | via process data | Analog 0 to 10V |

| Gripping force [N] | 360 | 360 | 500 | 500 |

| Stroke per jaw [mm] | 16 | 16 | 20 | 20 |

| Weight [kg] | 0.83 | 0.83 | 1.3 | 1.3 |

Customer-specific solutions

GRIPPERS FOR THE MEDICAL, PHARMACEUTICAL, FOOD AND ELECTRICAL INDUSTRIES

Reliable gripping with a hygienic design

We can offer customer-specific variations based on our series GEP2000 and GEH6000 grippers, which are ideal for use in sensitive applications. By using enclosures that conform to FDA and GMP requirements, we can react quickly and provide attractive pricing options.

For example, customized grippers are already being used to transport vials and syringes in a laboratory's filling system and to help in semiconductor manufacturing. The modified housing ensures that the end effectors meet the strictest hygiene and cleaning requirements.

Resistance against aggressive cleaning agents

We use materials that are resistant against aggressive cleaning agents (hydrogen peroxide / H2O2, etc.).

Reduced particle emissions in accordance with GMP

We ensure cleanroom suitability with reduced particle emissions in accordance with GMP and ISO 14644.

FDA-compliant design

We only use materials that correspond to the requirements of the FDA material list.

Food-grade H1 grease

Our solutions correspond to the strict requirements of FDA regulation 21 CFR 178.3570.

Specially sealed

The customer-specific grippers based on the GEP2000 and GEH6000 series correspond to protection class IP 54 and/or 65 (protection class in accordance with IEC 60529).

STANDARD INTERFACE

For robots and end effectors

MATCH End-of-Arm Ecosystem

Equipped with an extensive range of functions and universal communication interfaces, MATCH is compatible with all common lightweight robots on the market – an ideal system for cobots and conventional 6-axis robots.

MATCH components can be recognized by this symbol.

Product of the Year 2023

The MATCH End-of-Arm Ecosystem is a milestone for robotics and was honored as "Product of the Year 2023" by WEKA Business Medien GmbH. In the "Handling, Installation and Production Logistics" category, the Zimmer Group was able to win out against 11 competitors and take first place.

Applications as varied as the system

Whether mobile and collaborative robotics or fully automated applications: Just one flexible system gives the user access to a nearly unlimited range of uses from production and installation to warehouse logistics, shipping and even laboratory automation.

Typical tasks for the system include pick&place, order picking, packaging and palletizing, checking and testing. Various mechanical and vacuum grippers can be selected corresponding to the workpiece and handling task. If the requirements change, the system can be quickly and easily adapted.

Standardization of the robot interface

One robot module – the entire spectrum of compatible end effectors. Regardless of whether cobots, lightweight robots or conventional robots.

Easy installation – Plug & Work

Simplified machine communication thanks to the required communication parameters.

Flexible

Direct control and monitoring of robot functions using a software solution.

Complex robot applications

Can perform various tasks on a workpiece via automated end effector replacement.

MATCH microsite

Experience the future of robotics and revolutionize your industrial automation! The MATCH microsite gives you an overview of the most important information about this pioneering robot module, along with the opportunities that open up for you when using MATCH!

guideZ FOR ROBOT

AUTONOMOUS COMMUNICATION

Interactive programming

The Zimmer Group has developed a new innovation for existing platform-independent connections as well as for those of all leading robot manufacturers via a combination of SCM and the Comfort app. Communicating with your products via the robot module using an external HMI on a laptop is no longer necessary because, thanks to guideZ for Robot, communication can now be done autonomously via the teach panel.

Your grippers no longer have to be set up via a network interface using a laptop. This can now be done directly from the panel via the robot’s own interface. This increases not only efficiency, but also enables programming and parameterization without extensive programming knowledge.

Thanks to the upgrade to existing Zimmer Group programs, the hardware, electric grippers and the Comfort app remain unchanged. Your robot applications can be put into operation easily using the included programming tools from the Zimmer Group. The Comfort app ensures uncomplicated and fast commissioning and enables easy gripper control, operation and parameterization.

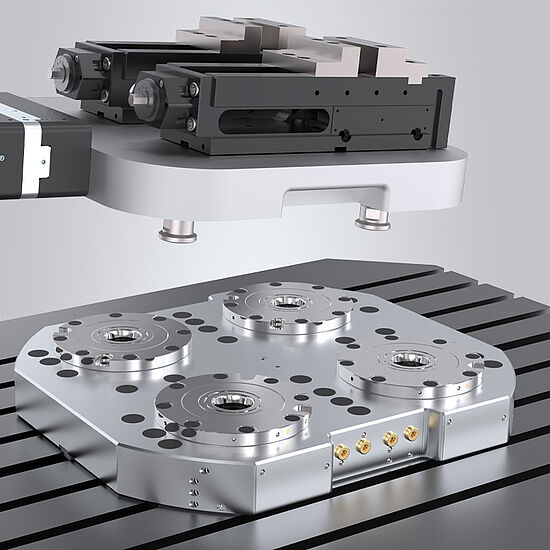

PALLET CHANGER

PRODUCT LAUNCH

Safely clamped in all areas of use

With the pallet changer, the Zimmer Group is expanding the zero-point clamping system product range. Along with changing pallets in tooling machines, it also offers numerous other applications, for example, the handling of components in portals or on robots with high repeat accuracy.

Because of the slim design and low set-up of the clamping plate and clamping pallets, you get both close-proximity pallet loading on the machine table as well as maximum use of the machine space. High clamping forces create an extraordinarily rigid system, whose excellent holding force enables the highest torque as well as a highly precise connection between the robot and the clamping plate. This makes the handling of heavier pallets, in particular, easier and safer.

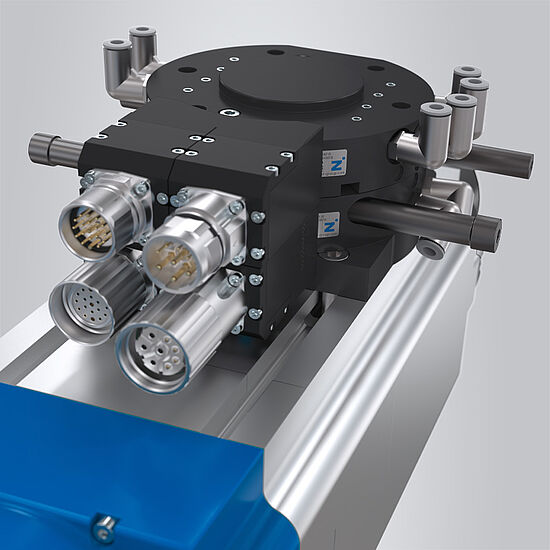

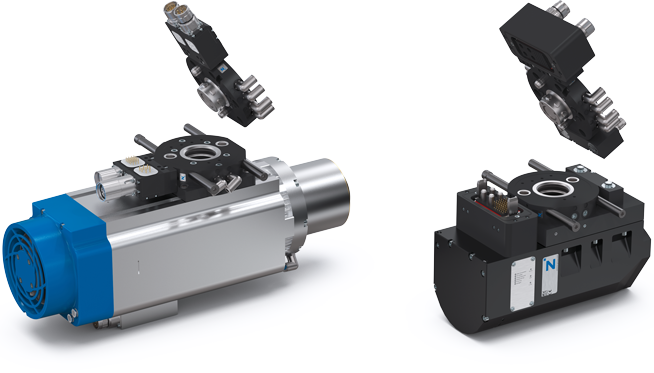

NEW TOOL CHANGER

WWS SERIES

Optimal coordination

With the WWS series, the Zimmer Group offers the right changing unit for robots and optimally expands the modular construction system of motor spindles. The changing unit for robots includes a suitable storage station and is specially designed for the motor spindle. It can also be installed later if needed, which would enable an automatic spindle change. Specially designed robot changing units are available for motor spindles that are designed for use with robots. The robot changing units provide a reliable interface between the robot and motor spindle. The loose part is attached to the motor spindle, while the stationary part is mounted at the end of the robot arm. A storage station is supplied to set the motor spindle aside when it is not being used.

PRODUCT WORLD AND INNOVATIONS

AROUND THE CLOCK

Our virtual trade show booth

Visiting our virtual booth can benefit you in many ways. Unlike at a visit to a trade show, there are no costs for you. There are no entrance fees, travel costs, hotel costs, etc. You can conveniently visit our virtual booth from your home or office at any time, 24/7. Meet our employees in the digital world and ask questions easily and directly either online or via the contact form.

Trade show tours

A visit to our virtual showroom is worthwhile any time.

The following features are sure to impress you, even in virtual form:

- Rotating booth. Animated camera movements lead to our six technology areas and to our own business division

- Clickable hot spots and compact information. All presented exhibits can be experienced digitally. Each features a content window with the particular product advantages for our products. Another click takes you to greater detail with additional images and data sheets. Need even more information? Our video presentation can help.

- Exhibits impressively prepared in digital form. There are rotating 3D models of our products so that they can be viewed from all sides

- Content available in several languages. All information for our virtual booth can be accessed in Zimmer Group’s communication languages of German, English, French, Italian, Polish, Slovak, Spanish, Chinese and Korean.