GEP2016IO-12-B-01

2-Jaw Parallel Grippers

Series GEP2000

"The electric compact one"

- Largest stroke in small installation space

Do you require a large stroke, due to the fact that you are operating either a form fit gripper or a large range of parts but the installation space and the load capacity of your application is limited? Then this gripper is perfect for you! - The simplest activation

It is your choice whether you want to control the gripper by means of I/O ports—like a valve—or if you prefer the version with IO-Link. Both have this in common: they are easy to integrate into your control system. - Positionability via IO-Link

Allows you to position the gripper jaws of the IL-03 and IL-43 variant. In this way, the stroke can be flexibly adapted to the workpiece, which saves time in the process and prevents interfering contours.

Equipment/Options

10 million maintenance-free cycles (max.)

10 million maintenance-free cycles (max.) Gripping force adjustable

Gripping force adjustable

Technical Data

| Control | I/O |

| Stroke per jaw | 16 [mm] |

| Position sensing analog 0 to 10 V | Yes |

| Self locking mechanism | mechanical |

| Control time | 0,055 [s] |

| Dead weight of mounted gripper finger max. | 0,21 [kg] |

| Length of the gripper fingers max. | 120 [mm] |

| Repetition accuracy +/- | 0.02 [mm] |

| Operating temperature | 5 ... +60 [°C] |

| Voltage | 24 [V] |

| Current consumption max. | 2 [A] |

| Minimum positioning path per jaw | 0.5 [mm] |

| Clean room applications according to DIN EN ISO 14644-1 | 2 |

| Protection to IEC 60529 | IP40 |

| Weight | 0.94 [kg] |

Benefits in detail

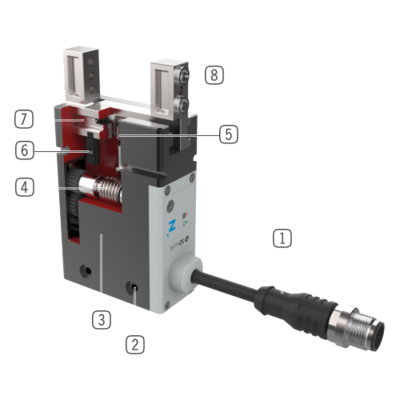

- Control

Via I/O ports (IO) or via IO-Link (IL) - Mounting and positioning

mounting possible from several sides for versatile positioning - BLDC motor

wear-resistant brushless DC motor - Helical worm gear

self locking mechanism in case of power drop - Synchronization

via rack and pinion - Position sensing

Permanent magnet for direct query of jaw movement via magnetic field sensors - Gripper jaw

individual gripper finger mounting - Removable centering sleeves

quick and economical positioning of the gripper fingers