Automated item picking

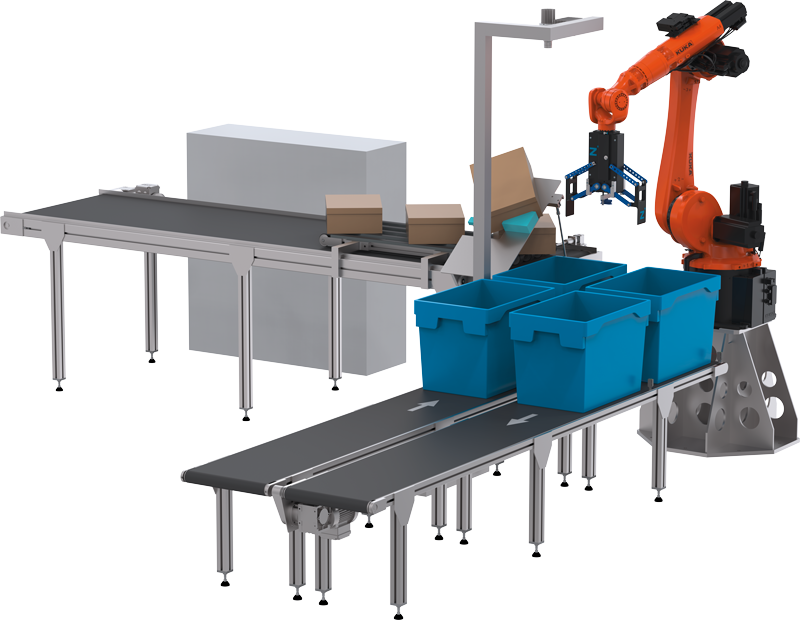

The logistics and intralogistics division is growing rapidly due to the digital transformation, the growing acceptance of online commerce and, of course, the pandemic. Zimmer Group is an experienced partner for your logistics/intralogistics application. Our expertise includes nearly all inbound and outbound industries, from automated item picking to AI-guided vision systems.

Key features and added value:

- Automated item picking system from Zimmer Group for fast and precise order picking: loading or unloading trolleys

- Workpiece: boxes

- Possible integration in place of a manual workstation

- Detection of position, orientation and surface (e.g. cover detection) of the workpiece with the vision system

- Zimmer Group scope of delivery: Complete cell, gripper system with vision technology or just the gripper system

Performance data:

- Pick rate > 600 picks/hr

- Workpiece weight: Up to 5 kg

- Workpiece size: (depends on the gripper stroke): 120 - 255 mm

- Gripper weight: 11 kg

APPLICATION EXAMPLE: SHOE BOXES

- The boxes can be placed with the top side down or upright in the container.

- The vision system is able to detect the number of boxes, the alignment, the XYZ coordinates and the cover. As a result, it can determine a grip point.

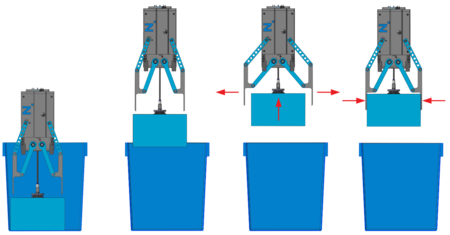

- Various gripping strategies are possible:

- Direct mechanical gripping with gripper jaws

- Vacuum suction cup in the first step to pull the box between the gripper jaws and mechanical gripping in the second step

- Moving the box within the container with the gripper jaws to reposition it

- The vacuum suction cup can be placed on the cover to prevent the cover from opening while the robot is moving.

- With the intelligent vision, collisions can be detected and thus prevented

- Shoe box detection and determining the pick order

Technical data of the gripper

- Flexible gripper system for handling boxes

- Stroke per gripper jaw: 140 mm

- Integrated Z-axis with vacuum suction cup for removing boxes on the edge or nearby

- With the low interference contours of the gripper, the design makes it possible to dip into a trolley

- The gripper can be adjusted to the specific application