Intelligent Products

With a view towards simplifying work with robots more and more, we are working on intelligent products that enable tools to be changed more quickly, for example, and contribute to enhanced safety. Our goal is to make your selection easier with clever solutions, such as the gripper finder and our coordinated products.

GEP2000 SERIES – THE ELECTRIC COMPACT GRIPPER

- Largest stroke in small installation space – Do you require a large stroke because you operate either a form-fit gripper or a large range of parts, but the installation space and the load capacity of your application is limited? Then this gripper is perfect for you!

- Simple activation – It is your choice whether you want to control the gripper by means of I/O ports like a valve or if you prefer the version with I/O link. Both have one thing in common: They are easy to integrate into your control system.

- Positionable via I/O link – Gives you the ability to position the gripper jaws of the IL-03 variant. This means the stroke can be adjusted to the workpiece with a great deal of flexibility. As a result, you save time and avoid interference contours in the process.

For greater process reliability and efficiency of your medical and pharmaceutical applications

Learn why we recommend the GEP2000 series gripper for the medical and pharmaceutical industry, what mechanical self-locking entails and why it is so important.

Product Range 5000

The universal gripper, perfect for any application. From angular grippers to concentric grippers and parallel grippers – with the 5000 series, the choice is yours!

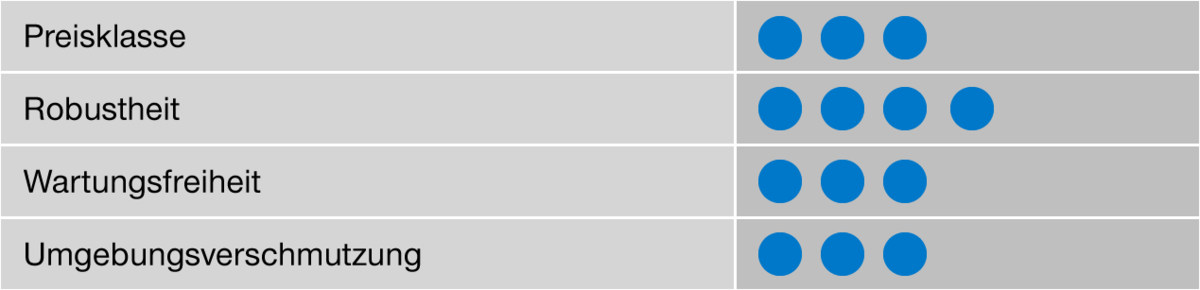

- Steel Linear Guide – our most process reliable and precise guide

- Corrosion protected and sealed up to IP67 – for the toughest environment parameters

- Up to 30 million cycles with no maintenance required – worry-free production

- Pneumatic, pneumatically intelligent, electrical – flexible with three drive concepts

- One mounting drill pattern for three drive concepts – no engineering effort when replacing

The best –

Steel Linear Guide

With the Steel Linear Guide, the gripper features a guide that takes the proven principle of the linear guide and combines it with state-of-the-art sealing and coating technology. This gives you the most robust gripper in combination with corrosion protection and IP64 protection class currently available on the market.

The alternative –

Aluminum Linear Guide

They are the alternative because they are technically superior to all T-slot grippers and at least equal to multi-tooth guided grippers. They are "everyday grippers", sufficient for most applications, and offer 15 million cycles maintenance-free.

FROM PNEUMATIC TO ELECTRICAL ILLUSTRATED BASED ON THE 5000 SERIES

See for yourself what sets the grippers of the 5000 series apart, what drives are supported and what makes the steel guide of these grippers so special.

We make selecting grippers and accessories fast and easy. An intelligent search consisting of the most important selection criteria quickly shows you sound suggestions for selection.

User-friendly overview delivers comprehensive results. Users enjoy the convenience of selecting the model that is right for them from a wide variety of grippers (including accessories). The most important data is presented clearly along with the relevant product recommendations.

Refined selection through filters. Additional filters and specific application data make it possible to narrow the search further.

The solution you want, with the mobile availability you need. The product finder is web-based and there is no need to install any software.

Getting to the product quickly – with our gripper finder!

Which gripper is the right one for me? We show you how to use our gripper finder to find suitable products in just a few clicks, then compare them and send them to us for review.

The best of both worlds – the new flexible tool changer

Learn how the FWR50 works, what differentiates the flexible tool changer from the MATCH ecosystem, how the energy elements operate on this tool changer and how it changes between different end effectors automatically or manually.

CRR50 COLLSION PROTECTION

- Adjustable triggering sensitivity – By controlling the air pressure, you can optimally match the sensitivity to your application.

- Integrated sensor – If there is a collision, the integrated sensor gives a signal to the control system to trigger an emergency stop.

- Automated reset – After an emergency stop, you can reset the collision protection from a safe distance. This is an advantage primarily when entering the system is undesirable, dangerous or is possible only with difficulty.

IMPROVED XYR SERIES AXIS COMPENSATION MODULE

- Adjustable compensation force and stroke – Using adjustment screws, you can adapt the characteristics of the compensation optimally to your application in the shortest possible time

- Flat design – This feature reduces the torque load on your robot to a minimum, allowing the use of smaller, more cost-effective installation sizes

- Can be fixed in place centrally or eccentrically – You can clamp or centrally lock the compensation position, depending on your requirements. An aid for optimal processes

Process reliability options for your robot application

We demonstrate CRR50 collision protection, explain what happens during a collision and how collision protection protects parts. You also learn how the CRR can be used for unsafe processes, because after a collision, it automatically resets itself to the target position.

INFORMATION

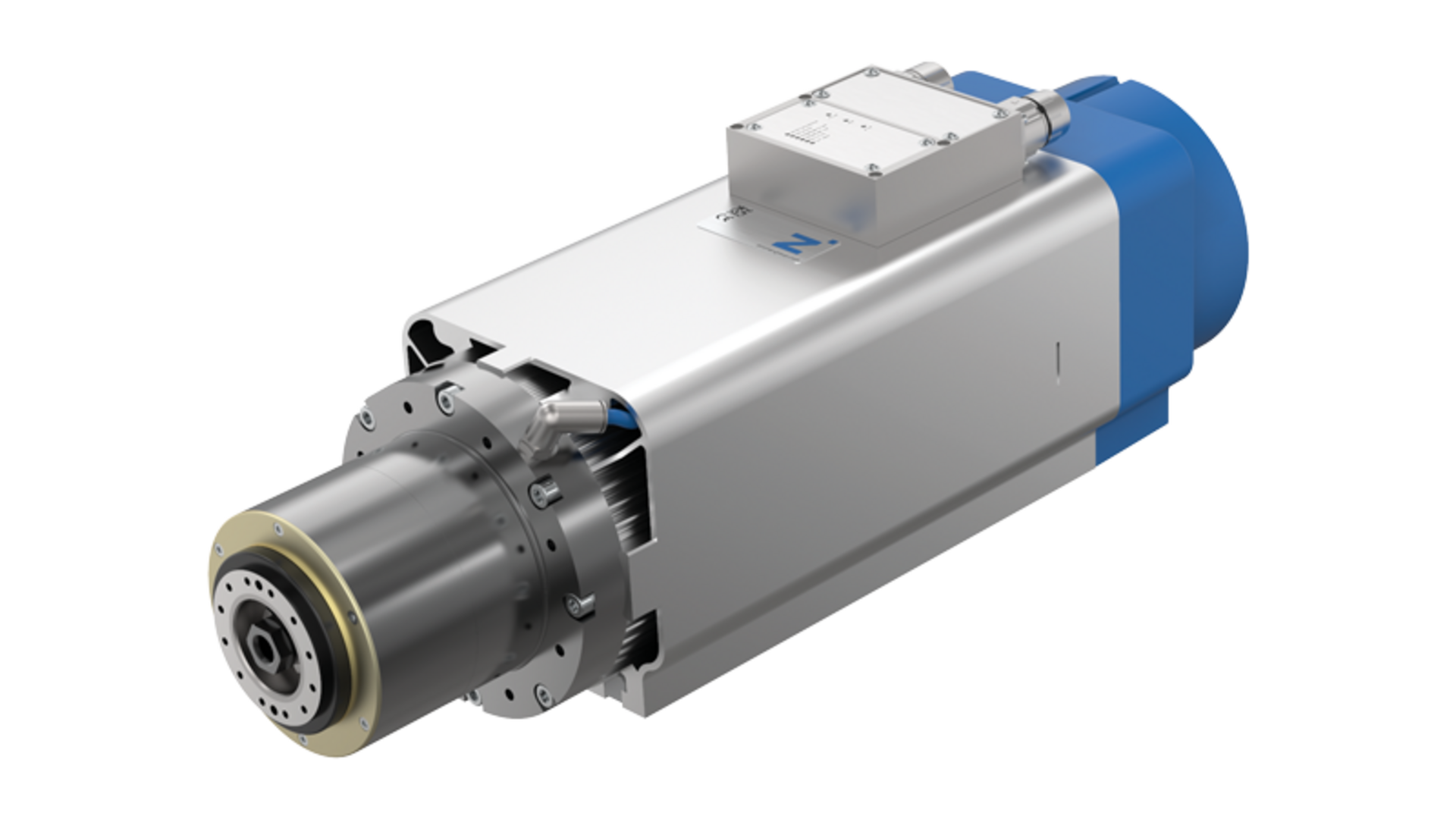

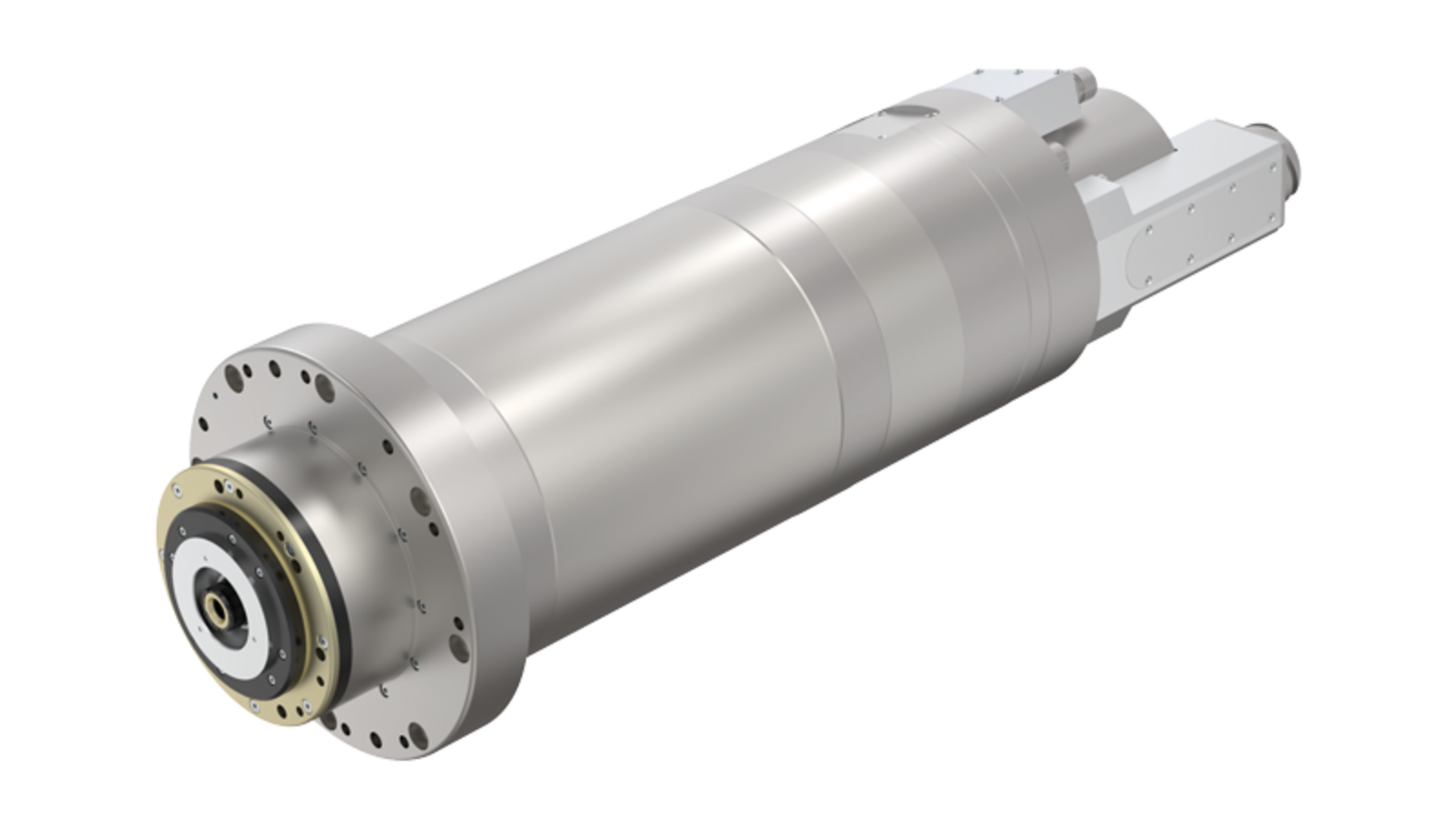

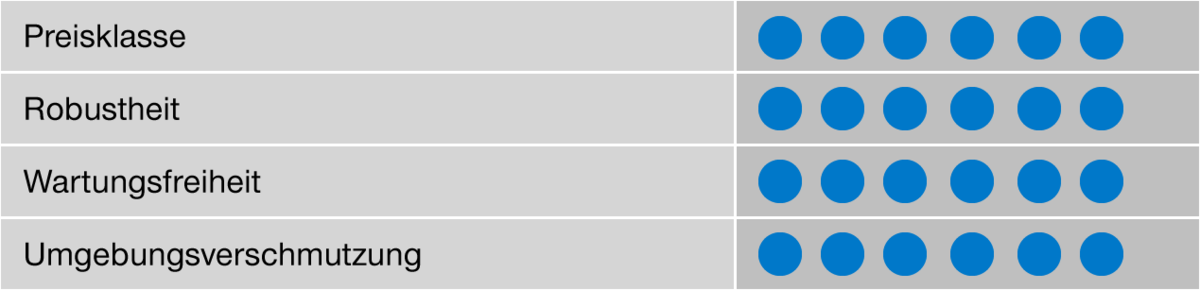

- Air and water-cooled high-frequency spindles in a variety of output ranges

- Support on topics such as power dimensioning, energy supply, cooling or integration into the control system or service

- Repair and on-site service by expert staff

- Spindle I/O link communication module allows condition monitoring or predictive maintenance

- Extremely reliable, high performance density and high compatibility

Everything from a single source – Reduced commissioning effort for your application with our spindles

Discover how smoothly our products interact with one another, making commissioning so much easier: Standardized changeover contacts and energy elements ensure a wide variety of combinations and consistently strong performance.