Tool Changers

Series WWR1000

- Secure hold during pressure drop

A redundant system, created by the combination of spring accumulator and a self locking mechanism, guarantees a safe machine - Handling weight from up to one tonne

Automated changes can be carried out by this changer with process reliability even with the largest robots - Inexhaustible variety of media transfer systems

No matter which medium you would like to transmit, we will draw from our wealth of experience in implementing projects and find a solution to suit your needs!

Installation Size: WWR1160 | ||||

| Order-No. | Connecting flange according EN ISO 9409-1 | Electrical energy transfer | Fluid energy transfer | |

|---|---|---|---|---|

| WWR1160F | TK 160 | optional | optional | |

| WWR1160L | TK 160 | optional | optional | |

Installation Size: WWR1200 | ||||

| Order-No. | Connecting flange according EN ISO 9409-1 | Electrical energy transfer | Fluid energy transfer | |

| WWR1200F | TK 200 | optional | optional | |

| WWR1200L | TK 200 | optional | optional | |

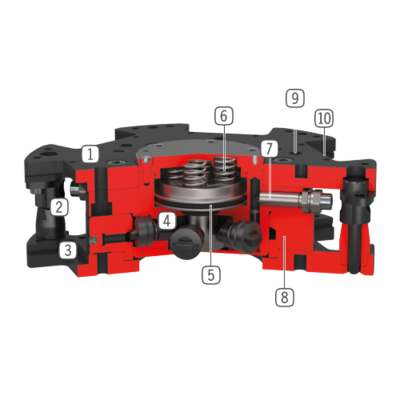

- Fix part

For robot side assembly - Centering pins

twist protection and positioning for loose part - Loose part

For tool side assembly - Locking bolt

adapted to the clamping sleeve - Drive

double-acting pneumatic cylinder - Integrated spring

energy storage in case of drop in pressure - Piston position sensing

Via inductive proximity switch - Locking sleeve

- Robot flange

partial mounting circle in accordance with EN ISO 9409-1 - Mounting for energy element